Cooling Down & Increasing Power On The ‘71 Chevy Caprice

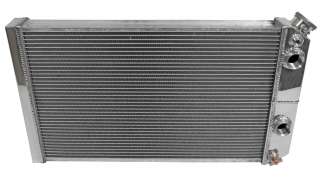

Cool Running – We install the cooling system on our ’71 Caprice and then put the pedal to the metal to give you the lowdown on electronic throttle vs mechanical.

Season 10

Episode 11

Hosts: Tommy Boshers, Joel McMillan

First Air Date: August 14, 2023

Duration: 21 minutes 27 seconds