More Slant Six Episodes

Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Magnaflow

Exhaust System, Hot Rod Kit, Header-Back, Stainless Steel, Natural, 2.50 inch Diameter, Universal, Kit

ADDCO Manufacturing,Inc.

Sway Bar, Black, Steel, Front, 1 1/8 in. Diameter, Dodge, Plymouth, Kit

ADDCO Manufacturing,Inc.

Sway Bar, Black, Steel, Rear, 3/4 in. Diameter, Dodge, Plymouth, Kit

Classic Performance Products

Disc Brakes, Power, Front, 11 in. Diameter Rotors, Single-Piston Calipers, Dodge, Plymouth, Kit

Edelbrock

Carburetor, Performer, 500 cfm, 4-Barrel, Square Bore, Manual Choke, Single Inlet, Silver, Each

Hooker Headers

Headers, Super Competition, 6-2, Steel, Painted, Dodge, Plymouth, 198, 225, L6, Pair

Offenhauser

Intake Manifold, Single Plane, Aluminum, Natural, Square Bore, 4-Barrel, Chrysler, 170, 225, Slant Six, Each

Yukon Gear & Axle

Yukon standard open spider gear kit for 7.25" Chrysler with 25 spline axles.

Yukon Gear & Axle

High performance Yukon ring & pinion gear set for Chrysler 7.25" in a 3.21 ratio.

Classic Industries

H24385 - 1967-76 mopar a-body hotchkis 3 leaf 130 lb/in spring rate geometry correcting sport leaf springs

Coker Tire

BF Goodrich Radial Redline, 225/70/R15

Coker Tire

BF Goodrich Radial Redline, 235/70/R15

Coker Tire

Mopar Rallye Cap Dark Gray

Coker Tire

Mopar Rallye Wheels 15x7

Coker Tire

Trim Rings for Wheels 15

Dake

G-75 220/440-volt 3-phase, Belt Grinder

Goodson Shop Supplies

Electronic Scale-4100G

Goodson Shop Supplies

Rod Balancing Stand

Matco Tools

APF415 - 5 Piece Pickle Fork Kit

Matco Tools

MT2816K - Long Barrel Air Hammer Kit

Matco Tools

MV6830A - Shop Air Brake Bleeder / Evacuator

Mopar Performance

Air Filter Assembly, Round, Steel/Aluminum, Black Anodized Top with Mopar Logo, 2 3/4 in. Filter Height, Each

PowerTrain Products

Chrysler, a904, transmission w/ torque converter

RockAuto.com

A-1 CARDONE, Part #206184, Reman. w/ Reservoir; Does Not Include Reservoir Cap, Power Steering Pump

RockAuto.com

Four Seasons, Part #57059, Remanufactured, w/o Clutch, A/C Compressor

RockAuto.com

KYB Part #KG4509, Gas-A-Just, Shock Absorber

RockAuto.com

PRO Part # 8010354, Radiator

RockAuto.com

Radiator hoses: goodyear,lower hose pt#60664; gates, upper hose pt#20230

RockAuto.com

REMY Part # 20657, Premium Remanufactured w/ 2 Groove Pulley; 60 Amps

RockAuto.com

Steering components: idler arm pt#4501026, pitman arm pt#mk7074, front inner tie rod pt#es401l, front outer tie rod pt#es401r, adjusting sleeves pt#4251000

The Industrial Depot

The Industrial Depot - Fasteners, Hardware and Shop Supplies

Episode Transcript

(ANNOUNCER)>> ENGINE POWER

COMPLETES THE CLASSIC CHRYSLER SLANT SIX

ENGINE BUILD AND FOUND A CLASSY PLACE TO PUT IT.

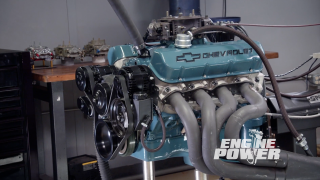

(MIKE)>> LAST WEEK ON ENGINE POWER YOU SAW US TEAR DOWN A 225 CUBIC INCH SLANT SIX, WHICH WAS CHRYSLER'S MOST DURABLE AND RELIABLE

ENGINE EVER BUILT. UNFORTUNATELY OURS SAT OUT IN THE ELEMENTS AND HEAVY CORROSION KEPT US FROM REUSING IT. SO WE STARTED WITH A LATER MODEL BLOCK AND HAD IT FRESHLY MACHINED. NOW THE CRANK WAS INSTALLED WITH AN UPGRADED ONE PIECE REAR MAIN SEAL AND RECONDITIONED RODS WERE DROPPED THROUGH THE BORES WITH NEW PISTONS ATTACHED. A COMPLETELY REFRESHED CYLINDER HEAD WAS DROPPED ON THE DECK AND THE ENGINE WAS FINISHED OFF WITH PERFORMANCE PARTS FROM HOOKER, OFFENHAUSER, AND EDELBROCK. WE COULDN'T DYNO OUR SLANT SIX BECAUSE THE BELL HOUSING DIAMETER IS TOO SMALL AND IT WOULDN'T

DOCK UP TO THE DYNO. BUT WE TOLD YOU WE HAD A HOME FOR IT, AND IT DOESN'T GET ANY BETTER THAN THIS '71 DUSTER.

(KEN)>> WHEN IT'S COLD IT SPITS, IT SPUTTERS. I'VE GOT TO WARM IT UP. IT'S GOT AN EXHAUST LEAK. SO IT JUST MAKES A LOT OF RACKET.

(MIKE)>> AND HERE'S ITS OWNER KEN SIMINGTON, WHO HAS AN EMOTIONAL ATTACHMENT TO THIS WORK IN PROGRESS.

(KEN)>> YOU KNOW THIS CAR IS OVER 40 YEARS OLD.

THERE'S NOT THAT MANY OF THEM OUT THERE RUNNING. MAINLY, SINCE MY WIFE BOUGHT IT BRAND NEW. WHEN I FIRST MET HER SHE WAS BLOND, SHE WAS CUTE. THE TIME I SAW HERE SHE SHOWED UP IN THIS RED CAR. THE RED CAR AND THE BLOND HAIR WENT TOGETHER AND

I KNEW RIGHT THEN I WAS IN TROUBLE. SHE LOVED IT, IT WAS HER FIRST CAR. SHE MIGHT LOVE IT MORE THAN SHE DOES ME.

I'VE NEVER ASKED THAT QUESTION TO HER.

(MIKE)>> RECENTLY KEN'S SON PAID TO GET IT BACK TO

ITS ORIGINAL CONDITION BY SENDING IT TO A LOCAL BODY AND PAINT MAN WHERE THE REFRESH STARTED. THE CAR WAS STRIPPED TO BARE METAL AND RECEIVE A

COUPLE OF NEW PANELS BEFORE THE ORIGINAL COLOR WAS LAID BACK DOWN. NOW THE FINAL TOUCH WAS THE BLACK PIN STRIPPING THAT GAVE IT A NICE BUT SUBTLE LOOK. KEN'S NEXT UPGRADE IS OBVIOUS.

(KEN)>> EVERYONE WILL HAVE A 340 OR A 440 IN THE PLYMOUTH/CHRYSLER BODY. I DON'T WANT TO RACE IT, I JUST WANT TO DRIVE IT AROUND AND SHOW IT TO PEOPLE, AND EDUCATE THEM ABOUT WHAT TYPE OF MOTORS WHERE DONE IN THE '60'S

AND '70'S, AND THE SLANT SIX IS A CLASSIC.

(MIKE)>> AND THAT'S WHY WE ASKED HIM TO BRING THE CAR HERE.

THIS IS ACTUALLY MORE FUN THAN DYNO'ING A BIG POWER CAR.

(PAT)>> I FEEL SAFER BUT NOT REALLY. JUST FOR FUN, LET'S SEE WHAT THIS ONE HAS LEFT IN IT.

(MIKE)>> ALRIGHT, HERE WE GO.

(PAT)>> WE'LL MAKE THE PULL FROM 2,000 TO 3,800 AND HOPE WE CAN MAKE IT THERE. THIS ISN'T THE ORIGINAL 225 ENGINE. IT WAS REPLACED WITH A 95 HORSEPOWER 1975 MODEL IN THE '80'S, AND IT'S SEEN A LOT OF MILES SINCE, MAKING THIS DUSTER THE PERFECT HOME FOR OUR LEANING TOWER OF POWER. I THINK WE'RE THERE. AT A WHOPPING 64 MILES PER HOUR IT MADE JUST OVER 70 HORSEPOWER, AND THE GRAFPH TELLS THE STORY.

(MIKE)>> WE'RE NOT LAUGHING AT IT CAUSE THIS WAS A STAPLE OF ECONOMICAL PERFORMANCE BACK IN THE DAY. SO TO GET KEN BACK IN RELIABLE CRUISING STATUS WE'LL BE UPGRADING THE COOLING SYSTEM FROM SUMMIT RACING, A DRUM TO DISC BRAKE CONVERSION KIT FROM CLASSIC PERFORMANCE PRODUCTS, ALL NEW STEERING LINKS, SHOCKS, AND MOUNTS FROM ROCK AUTO, A 3.21 RING AND PINION FROM YUKON GEAR AND AXLE, AND ADCO SWAY BARS FOR BETTER HANDLING. FROM THE TOP WE'LL START REMOVING EVERYTHING WE CAN WITHOUT DRAINING ANY FLUIDS YET. THIS WILL INCLUDE THE SINGLE BARREL CARBURETOR, INTAKE MANIFOLD, AND THE CAST IRON EXHAUST MANIFOLD.

THIS DUSTY WAS FACTORY EQUIPPED WITH AIR CONDITIONING, AND IT'S GOING BACK THAT WAY.

NOW IT'S BEEN OUT OF SERVICE FOR QUITE A FEW YEARS, SO THERE IS NO REFRIGERANT IN THE LINES, ALLOWING US TO REMOVE THEM WITHOUT AN EVAC SYSTEM. NOW WE CAN REMOVE THE MASSIVE STARTER, AND USING OUR MATCO EVAC CANISTER, DRAIN AS MUCH POWER

STEERING FLUID OUT OF THE RESERVOIR AS POSSIBLE. THE SAME GOES FOR THE MASTER CYLINDER.

(PAT)>> NOW WE CAN LOOSEN THE ALTERNATOR TO REMOVE THE BELT. THE UNBOLT THE MECHANICAL FAN AND REMOVE IT WITH THE WATER PUMP PULLEY. NOW WE HAVE ACCESS TO THE FASTENERS THAT HOLD THE

A/C COMPRESSOR BRACKET IN PLACE SO THE WHOLE

ASSEMBLY GOES AS WELL. FROM UNDERNEATH WE CAN DRAIN THE COOLANT AND THE ENGINE OIL, REMOVE THE TRANSMISSION LINKAGE, UNBOLT THE TORQUE CONVERTER FROM THE FLEX PLATE, REMOVE THE TRANSMISSION COOLER LINES, AND GET AS MUCH FLUID OUT OF THEM AS WE CAN.

(MIKE)>> NOW THE DRIVE SHAFT CAN BE PULLED AND THE BELL HOUSING BOLTS SO WE CAN DROP THE TRANSMISSION. THIS IS A 904 THAT'S GETTING REPLACED WITH A REMANUFACTURED UNIT. WITH THE ENGINE MOUNT NUTS REMOVED.

(PAT)>> YOU'RE GOOD ON THE BACK.

(MIKE)>> WE CAN HOIST THIS 225 OUT OF THE CAR TO MAKE

WAY FOR THE NEW BULLET.

(MIKE)>> WE'RE BACK AND BEFORE THE NEW ENGINE AND TRANS GOES IN, WE HAVE PLENTY TO DO UNDERNEATH. WHEN'S THE LAST TIME YOU POPPED OFF A HUB CAP?

LOOKS LIKE IT'S BEEN A WHILE FOR KEN TOO. THE FRONT WHEELS ARE 14 INCH IN DIAMETER AND CANNOT BE USED WITH OUR FRONT DISC BRAKE UPGRADE SINCE THEY REQUIRE A 15 INCH WHEEL FOR CLEARANCE. SO AWAY THEY GO. THE NASTY, DIRTY DRUM BRAKE ASSEMBLIES ARE THE NEXT PIECES TO COME OFF. NOW THE EASIEST WAY IS TO SEPARATE THE UPPER AND LOWER BALL JOINTS AND REMOVE THE WHOLE SET UP AS AN ASSEMBLY. FOLLOWED BY THE UPPER CONTROL ARMS AND THE SHOCK ABSORBERS. WE'RE ALSO GOING TO REPLACE THE BUSHINGS IN THE STRUT RODS SO THEY CAN BE REMOVED AS WELL. THIS REQUIRES REMOVING THE TORSION BAR BY LOOSENING THE NUT UP FRONT AND REMOVING THE RETAINING CLIP AT THE BACK. NOW THE BAR CAN BE PUSHED REARWARD SO WE CAN REMOVE THE LOWER CONTROL ARM ASSEMBLY.

(PAT)>> SINCE THE UPPER CONTROL ARMS ARE SHINY NEW, WE'LL CLEAN AND PAINT THE LOWERS TO MATCH THEM WITH VHT'S BLACK EPOXY PAINT, WHICH IS RUST AND SALT RESISTANT. AS THEY'RE DRYING, WE CAN PUT IN THE UPPERS FROM CLASSIC PERFORMANCE THAT ARE A DIRECT REPLACEMENT AND COME READY TO BOLT IN WITH NEW BUSHINGS AND BALL JOINTS ALREADY INSTALLED. NEW BUSHINGS AND WASHERS ARE GOING ON THE STRUT RODS TO ELIMINATE MOVEMENT THAT CAN EFFECT THE CAR'S ALIGNMENT WHILE DRIVING. ON THE OTHER SIDE OF THE STRUT ROD WE CAN ATTACH THE FRESHENED UP LOWER CONTROL ARM AS IT SLIDES THROUGH THE KMEMBER. AND WITH THE LOWER ARM FORCED DOWN WITH A PRY BAR, WE CAN REINSTALL THE ORIGINAL TORSION BAR AND RETAIN IT OUT BACK WITH THE FACTORY CLIP.

(MIKE)>> THIS DRUM TO DISC BRAKE CONVERSION FROM

CLASSIC PERFORMANCE FITS '63 THROUGH '76 "B" AND "E" BODY MOPARS. NOW IT COMES WITH AN 11 INCH VENTED ROTOR THAT HAS A FIVE ON FOUR AND A HALF INCH BOLT CIRCLE. NOW YOU ALSO GET A POWER ASSISTED BOOSTER, MASTER CYLINDER, AND PROPORTIONING VALVE ALREADY PREASSEMBLED. NOW THE KIT ALSO INCLUDES BRAND NEW SPINDLES, STEERING LINKS, CALIPERS, BRAKE PADS, AND THE HARDWARE FOR AN EASY INSTALLATION. THE SPINDLES MOUNT TO THE LOWER CONTROL ARMS FIRST USING THE SUPPLIED CASTLE NUT AND COTTER PIN. NOW THE UPPER CONTROL ARM CAN ATTACH TO THE SPINDLE THE SAME WAY. WITH THE BEARINGS AND SPINDLE GREASED, WE CAN SLIDE THE ROTOR INTO PLACE. THE SPINDLE NUT NEEDS TO BE FINGER TIGHTENED AS YOU ROTATE THE ROTOR. NOW ONCE ALL THE PLAY IS OUT OF THE BEARINGS, I'LL PRELOAD IT TO THE NEXT SLOT THE COTTER PIN CAN DROP INTO SINCE THE BEARINGS ARE NEW. THE NEW PAD CAN GO IN PLACE, FOLLOWED BY THE SINGLE PISTON CALIPER WITH THE OTHER PAD INSIDE OF IT. THESE CLIPS ARE ALL THAT RETAIN IT. SOMETHING ELSE KEN NEEDS BESIDES AN ENGINE ARE NEW SHOCKS. NOW THESE ARE KYB GAS ADJUSTS WE GOT IN FROM ROCK AUTO DOT COM. REPLACING THE BRAKE LINES IS A MUST FOR A CAR THIS OLD. THESE CAME WITH THE BRAKE CONVERSION.

(PAT)>> WITH NEW BRAKES AND SUSPENSION, WE'RE GONNA PUT THE FIRMNESS BACK IN THE STEERING WHEEL AS WELL. WE'RE GONNA REPLACE EVERYTHING IN IT THAT HAS A BALL JOINT BECAUSE FRANKLY WE KNOW THEY'RE ALL WORN OUT. AND THAT'LL INCLUDE A NEW PITMAN ARM, IDLER ARM, AND NEW INNER AND OUTER TIE ROD ENDS WITH NEW ADJUSTING SLEEVES. THE FIRST THING TO GO IS THE WORN OUT IDLER ARM. WE'LL USE OUR MATCO AIR HAMMER AND BALL JOINT

SEPARATOR TO REMOVE IT. THE NEW ONE CAN GO BACK IN ITS PLACE AND TIGHTEN DOWN. THE PITMAN ARM JOINT SEPARATES THE SAME WAY. THEN THE NUT SECURING IT TO THE STEERING BOX GETS REMOVED. WE'LL MAKE SURE TO NOTE THE POSITION ITS IN SO IT GOES BACK THE SAME WAY TO KEEP THE STEERING CENTERED. USING THIS PITMAN ARM REMOVER, WE'LL PULL IT OFF

THE SPLINE SHAFT THAT IT'S WEDGED ON TO, AND REPLACE IT WITH A NEW ONE MAKING SURE IT'S IN THE SAME LOCATION. NOW REATTACH THE DRAG LINK AND FINISH THE STEERING OFF WITH NEW TIE ROD ENDS AND SLEEVES. ALL THE FRONT END NEEDS IS OUR SLANT SIX TO FILL THAT BIG HOLE.

(ANNOUNCER)>> FROM THE STAND TO THE CHASSIS, THE ENGINE'S DROPPING IN AND SO DOES THE OWNER, COMING UP.

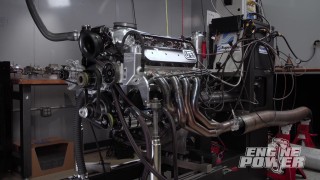

(PAT)>> WE'RE BACK AND READY FOR THE TRUE PURPOSE OF THIS CLASSIC ENGINE BUILD, BRINGING IT TO LIFE IN A CLASSIC, ERA CORRECT CRUISER.

WITH ITS NEW MOUNTS AND THIS DUSTER'S OIL PAN AND PICK UP INSTALLED, IT'S TIME TO DROP IT IN. I DON'T KNOW?

(MIKE)>> NICE, NICE!

(PAT)>> I'M GOOD RIGHT HERE.

HOW'S THAT OTHER SIDE?

OH, OH, SOMETHING HAPPENED!

(MIKE)>> IT'S IN!

(PAT)>> YES, YES, YES!

(MIKE)>> LOOK AT THAT WITH THE HEADER ON.

(PAT)>> NICE JOB.

(MIKE)>> VERY CLEAN LOOKING. POWERTRAIN PRODUCTS SENT US THIS REMANED 904 AUTOMATIC TRANSMISSION. NOW THEIR REBUILD PROCESS IS STRAIGHT FORWARD, KEEP THE ORIGINAL PARTS TOGETHER LIKE THE VALVE

BODY, CASE, AND HARDWARE LIKE IT LEFT THE FACTORY FOR A MORE RELIABLE UNIT. NOW ONCE ASSEMBLED, EACH ONE IS TESTED ON THEIR CUSTOM DYNOS THAT APPLY FORCE TO REPLICATE REAL WORLD DRIVING CONDITIONS SO THAT THEY KNOW IT'S A

SOLID UNIT BEFORE IT LEAVES THEIR FACILITY. THEY ALSO TRIPLE CHECK ALL THE THREADS AND FASTENERS TO INSURE PROPER TORQUE SPECS ARE ACHIEVED. PLUS THEY SUPPLIED THE TORQUE CONVERTER TO MAKE THIS A PACKAGE DEAL. A 318 DODGE RAM START THAT'S SMALLER AND SPINS FASTER WILL FIRE UP THE SLANTY. NOW THE BOOSTER AND MASTER CYLINDER ARE THE FINAL PIECES FOR THE FRONT BRAKES. THE ASSEMBLY BOLTS TO THE FACTORY MASTER CYLINDER STUDS. IT'S ALSO GETTING A NEW POWER STEERING PUMP AND A/C COMPRESSOR FROM ROCK AUTO. VOLTAGE WILL BE SUPPLIED TO THE BATTERY WITH A NEW ALTERNATOR FROM ROCK AUTO AS WELL. NOW THE FRESHLY PAINTED FAN CAN GO ON, AND TO DRIVE ALL THIS THREE NEW VBELTS. TO KEEP THE SLANT SIX COOL, THIS REPLACEMENT RADIATOR THAT'S A DIRECT FIT FROM ROCK AUTO. IT'S ALSO GETTING NEW HOSES.

IN FACT, WE FINISHED OFF THE ENTIRE ENGINE HOOK UP FROM THE WIRING TO THE FUEL LINES AND ON UP TO THIS CLASSIC MOPAR AIR CLEANER. WE TORE THE REAR END DOWN AS WELL, REPLACING THE 2.76 RING AND PINION WITH A 3.21 FROM YUKON GEAR AND AXLE. THE LEAF SPRINGS HAD LITTLE SPRING LEFT IN THEM. SO IT'S GETTING THESE FROM CLASSIC INDUSTRIES. AND PAIR THEM UP WITH NEW SHOCKS AS WELL.

FOR ROLLERS, COKER TIRE MOPAR RALLY WHEELS WITH TRIM RINGS AND CENTER CAPS, WRAPPED WITH BFG SILVER TOWN REDLINE RADIALS MADE BY THEM AS WELL, WHICH WILL COMPLIMENT THE CAR'S COLOR.

THE EXHAUST IS MADE FROM SCRATCH USING MAGNAFLOW'S TWO AND A HALF INCH STAINLESS PIPE AND AN 18 INCH STRAIGHT THROUGH MUFFLER FINISHED OFF WITH A TURN DOWN. AT THIS POINT THIS PROJECT IS DONE. AND JUST IN TIME!

(KEN)>> I FEEL LIKE A KID, I FEEL LIKE A KID AT CHRISTMAS.

(MIKE)>> WELL THE GOOD THING IS YOU CAN PULL IT OUT OF YOUR DUSTER, PUT IT IN A TRACTOR, AND PUT IT BACK IN THE DUSTER, MULTIPURPOSE!

(KEN)>> HOW MANY HORSE DO YOU THINK ITS PULLING?

(MIKE)>> WE'RE ABOUT TO FIND OUT.

(KEN)>> THOSE RED STRIPE TIRES ARE REALLY MAKING THAT PAINT JOB POP!

(MIKE)>> ALRIGHT KEN, WE DIDN'T TELL YOU, BUT WHEN YOU DROPPED THE CAR OFF WE WENT AHEAD AND PUT IT ON THE DYNO TO GET A BASE LINE. IT ONLY MADE 71 HORSEPOWER.

(KEN)>> ALRIGHT, AND HOW WAS THAT FOR

A MOTOR THAT AGE?

(MIKE)>> I THINK I HAVE A LAWNMOWER THAT MAKES A LITTLE MORE.

WE'RE TAKING THIS ONE TO A SAFE 4,500 RPM. LOOK AT THAT, 125 HORSEPOWER, 161 FOOT POUNDS OF TORQUE. WE'RE NOT DONE!

(KEN)>> OH WE'RE NOT?

(MIKE)>> NO, WE'RE GONNA PULL A LITTLE MORE OUT OF IT.

(KEN)>> OH REALLY!

(MIKE)>> I'LL MAKE A TIMING CHANGE. TWO MORE DEGREES OF INITIAL TIMING FOR A TOTAL OF SIX. 129 AND 164, PICKED UP THREE FOOT POUNDS AND FOUR HORSEPOWER.

(KEN)>> THAT'S IMPRESSIVE!

(MIKE)>> ONE LAST RUN WITH TWO MORE INITIAL DEGREES FOR A TOTAL OF EIGHT. HOW DO YOU LIKE THAT, 132, 170?

(KEN)>> THAT IS MARVELOUS.

(MIKE)>> TWO DEGREES PICKED IT UP THREE HORSEPOWER AND SIX FOOT POUNDS.

(KEN)>> AND YOU JUST CAN'T GET USED TO HEARING THAT ROAR. I CAN SEE IT ROLLING DOWN THE ROAD, JUST ZIPPING.

(MIKE)>> AND NOW HE CAN WITH ALMOST TWICE THE POWER HE STARTED WITH. HATS OFF TO KEN FOR KEEPING THE LEGEND OF THE SLANT SIX ALIVE!

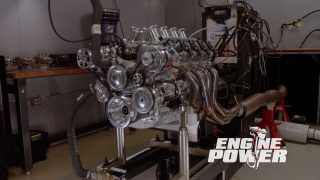

(PAT)>> AN IMPORTANT BUT OFTEN OVERLOOKED ASPECT OF

ENGINE BUILDING IS BALANCING, AND THERE'S TWO TYPES OF BALANCING THAT ARE DONE TO YOUR POWER PLANT WHEN YOU TAKE IT TO A MACHINE SHOP. THE FIRST IS DYNAMIC, MEANING SPINNING THE CRANK SHAFT WITH BOB WEIGHTS ATTACHED TO IT ON A MACHINE TO MEASURE THE BALANCE TOLERANCE. THE OTHER IS STATIC, MEANING WEIGHING ALL THE COMPONENTS AND MAKING THEM WEIGH WITHIN A CERTAIN AMOUNT. SINCE INLINE CRANKS DON'T REQUIRE A BOB WEIGHT TO

GET SPIN BALANCED, THE PARTS DON'T HAVE TO GO WITH THE CRANK TO THE MACHINE SHOP. MIKE AND I ARE GOING TO SHOW YOU HOW TO STATIC BALANCE PISTONS AND RODS YOURSELF WITH A FEW THINGS YOU MOST LIKELY HAVE LYING AROUND, LIKE A BELT SANDER, A DIE GRINDER WITH A FEW CARTRIDGE ROLLS AND CARBIDES, PLUS SOMETHING YOU'LL ACTUALLY HAVE TO BUY, LIKE THIS AFFORDABLE GOODSON BALANCING SETUP.

(MIKE)>> NOW DOING THIS YOURSELF IS GOING TO SAVE YOU MONEY AT THE MACHINE SHOP ON ANY INLINE ENGINE SINCE THEY WON'T HAVE TO TAKE THE TIME TO BALANCE THESE PARTS THEMSELVES. NOW WEIGHT MATCHING ALL OF THESE COMPONENTS IS GOING TO HELP THE ENGINE TO RUN SMOOTHER AND LAST LONGER NO MATTER THE APPLICATION. WITH OUR GOODSON GRAM SCALE FIRED UP, WE'LL

START BY WEIGHING THE PISTONS. BE SURE TO PRENUMBER THEM SO THAT YOU CAN KEEP TRACK OF THE WEIGHTS TO AVOID CONFUSION. NOW WHAT WE'RE LOOKING FOR ARE THE LIGHTEST ONES IN THE SET. NOW WE RECORDED THE WEIGHT OF EACH PISTON AND FOUND THE LIGHTEST ONES, WHICH COME IN AT 604 GRAMS. THE GOAL IS TO GET THEM ALL TO WEIGH WITHIN ONE GRAM OF EACH OTHER. SO THE NEXT STEP IS TO SET UP YOUR DIE GRINDER TO START REMOVING SOME MATERIAL. NOW MAKE SURE YOU ALSO HAVE YOUR SAFETY GLASSES ON FOR THIS BECAUSE YOU DON'T WANT THE ALUMINUM IN YOUR EYES.

(PAT)>> STARTING WITH THE HEAVIEST, WHICH WAS PONE AT 607 GRAMS, THE OBJECT IS TO LIGHTLY GRIND AROUND THE THICKEST PART OF THE PIN BOSS AREA, WHICH REMOVES WEIGHT. MAKE SURE TO REPEATEDLY CHECK IT ON THE SCALE DURING THIS PROCESS. SO FAR WE'VE REMOVED ONE GRAM. SO TWO MORE HAVE TO COME OFF TO REACH THE LIGHTEST PISTON WEIGHT OF 604. THIS IS ONE OF THOSE OPERATIONS WHERE YOU NEED TO TAKE YOUR TIME AND NOT GET TOO AGGRESSIVE.

IT'S EASY TO TAKE OUT TOO MUCH AND HAVE TO START THE WHOLE PROCESS OVER AGAIN. NOW IT GOES BACK TO THE SCALE AND THE MAGIC NUMBER HAS BEEN MET. SWITCHING TO A CARTRIDGE ROLL, WE CAN CLEAN UP ANY ROUGH EDGES THAT THE BURR CREATED AND THAT WRAPS UP THE PISTONS. WE ONLY HAD TO REMOVE WEIGHT OUT OF FOUR PISTONS BECAUSE TWO OF THEM WERE AT THE LOWEST WEIGHT OF 604. TYPICALLY PISTONS WILL WEIGH WITHIN FOUR GRAMS OF EACH OTHER, WHICH IS FINE FOR PRODUCTION ENGINES. WITH OUR CAPABILITIES AND OUR SET UP HERE, WHY NOT

MAKE THEM WEIGH ALL THE SAME LIKE A RACE ENGINE.

(MIKE)>> NEXT UP ARE THE RODS. NOW BOTH ENDS HAVE TO BE BALANCED BECAUSE THE SMALL END RECIPROCATES AND THE BIG END ROTATES. SO THEY EFFECT THE TOTAL BALANCE DIFFERENTLY. NOW THAT'S WHERE THE GOODSON ROD

FIXTURE COMES INTO PLAY. WE HAVE TO WEIGH THE BIG ENDS AND THE SMALL ENDS, AND FIND THE LIGHTEST ONES JUST LIKE THE PISTONS. WE'LL GO AHEAD AND START WITH THE BIG END. ACCURACY AND REPEATABILITY ARE KEY WHEN

USING THE FIXTURE. NOW I'LL PLACE THE ROD WITH THE BEARING TANGS FACING DOWN. NOW MAKE SURE THE ROD'S BEAM IS LEVEL AND IT'S NOT

BINDING IN THE FIXTURE. IF IT IS, THE READING WILL BE INACCURATE. ROD ONE'S BIG END WEIGHS 424 GRAMS. THE LIGHTEST BIG END IS ROD FOUR, WHICH IS 421. MATERIAL MUST BE REMOVED IN A SAFE SPOT ON THESE AS WELL. IN THIS CASE, THERE IS A DISTINCT BALANCE PAD ON EACH END. USING OUR DAKE BELT SANDER, WE'LL CAREFULLY SAND A LITTLE AT A TIME OFF THE HEAVIEST BIG END, REPEATEDLY CHECKING OUR PROGRESS TO MAKE SURE WE DON'T OVER DO IT. NOW I'M GONNA SET THE FIXTURE UP TO DO THE SAME PROCEDURE TO THE SMALL END OF THE ROD. WE JUST NEED TO MOVE THE BIG END BUSHING TO THE OTHER SIDE AND PRACTICE THE SAME REPEATABILITY AND ACCURACY AS BEFORE.

(PAT)>> THE LIGHTEST SMALL ENDS WERE 180 GRAMS AND THERE WERE TWO OF THEM. THE HEAVIEST WAS 182.

THAT'S A CLOSE RANGE FOR FACTORY PRODUCTION PIECES. NOW I'LL MATCH THE WEIGHTS TO THE LIGHTEST, THE SAME WAY AS THE BIG END ON THE BELT SANDER. WITH THE SMALL END WEIGHTS AT 180 GRAMS AND THE BIG END AT 421 GRAMS, ALL SAID AND DONE, THE ROD SHOULD WEIGH 601 GRAMS. AND HERE'S HOW TO CONFIRM THAT. YOU PUT THE ROD DIRECTLY ON THE SCALE AND THE MAGIC NUMBER WILL POP RIGHT UP, JOB WELL DONE. BALANCING THE PISTONS AND RODS YOURSELF IS ANOTHER TASK THAT YOU CAN ADD TO YOUR ENGINE BUILDING SKILL SET. PLUS WITH A SET UP LIKE THIS, YOU CAN PAY IT OFF AND EVEN PUT A LITTLE MONEY IN YOUR POCKET HELPING YOUR BUDDIES OUT TOO.

(MIKE)>> SO REMEMBER, KEEP YOUR BALANCE AND MAY THE SLANT BE WITH YOU. WE'LL SEE YOU NEXT TIME.

Show Full Transcript

(MIKE)>> LAST WEEK ON ENGINE POWER YOU SAW US TEAR DOWN A 225 CUBIC INCH SLANT SIX, WHICH WAS CHRYSLER'S MOST DURABLE AND RELIABLE

ENGINE EVER BUILT. UNFORTUNATELY OURS SAT OUT IN THE ELEMENTS AND HEAVY CORROSION KEPT US FROM REUSING IT. SO WE STARTED WITH A LATER MODEL BLOCK AND HAD IT FRESHLY MACHINED. NOW THE CRANK WAS INSTALLED WITH AN UPGRADED ONE PIECE REAR MAIN SEAL AND RECONDITIONED RODS WERE DROPPED THROUGH THE BORES WITH NEW PISTONS ATTACHED. A COMPLETELY REFRESHED CYLINDER HEAD WAS DROPPED ON THE DECK AND THE ENGINE WAS FINISHED OFF WITH PERFORMANCE PARTS FROM HOOKER, OFFENHAUSER, AND EDELBROCK. WE COULDN'T DYNO OUR SLANT SIX BECAUSE THE BELL HOUSING DIAMETER IS TOO SMALL AND IT WOULDN'T

DOCK UP TO THE DYNO. BUT WE TOLD YOU WE HAD A HOME FOR IT, AND IT DOESN'T GET ANY BETTER THAN THIS '71 DUSTER.

(KEN)>> WHEN IT'S COLD IT SPITS, IT SPUTTERS. I'VE GOT TO WARM IT UP. IT'S GOT AN EXHAUST LEAK. SO IT JUST MAKES A LOT OF RACKET.

(MIKE)>> AND HERE'S ITS OWNER KEN SIMINGTON, WHO HAS AN EMOTIONAL ATTACHMENT TO THIS WORK IN PROGRESS.

(KEN)>> YOU KNOW THIS CAR IS OVER 40 YEARS OLD.

THERE'S NOT THAT MANY OF THEM OUT THERE RUNNING. MAINLY, SINCE MY WIFE BOUGHT IT BRAND NEW. WHEN I FIRST MET HER SHE WAS BLOND, SHE WAS CUTE. THE TIME I SAW HERE SHE SHOWED UP IN THIS RED CAR. THE RED CAR AND THE BLOND HAIR WENT TOGETHER AND

I KNEW RIGHT THEN I WAS IN TROUBLE. SHE LOVED IT, IT WAS HER FIRST CAR. SHE MIGHT LOVE IT MORE THAN SHE DOES ME.

I'VE NEVER ASKED THAT QUESTION TO HER.

(MIKE)>> RECENTLY KEN'S SON PAID TO GET IT BACK TO

ITS ORIGINAL CONDITION BY SENDING IT TO A LOCAL BODY AND PAINT MAN WHERE THE REFRESH STARTED. THE CAR WAS STRIPPED TO BARE METAL AND RECEIVE A

COUPLE OF NEW PANELS BEFORE THE ORIGINAL COLOR WAS LAID BACK DOWN. NOW THE FINAL TOUCH WAS THE BLACK PIN STRIPPING THAT GAVE IT A NICE BUT SUBTLE LOOK. KEN'S NEXT UPGRADE IS OBVIOUS.

(KEN)>> EVERYONE WILL HAVE A 340 OR A 440 IN THE PLYMOUTH/CHRYSLER BODY. I DON'T WANT TO RACE IT, I JUST WANT TO DRIVE IT AROUND AND SHOW IT TO PEOPLE, AND EDUCATE THEM ABOUT WHAT TYPE OF MOTORS WHERE DONE IN THE '60'S

AND '70'S, AND THE SLANT SIX IS A CLASSIC.

(MIKE)>> AND THAT'S WHY WE ASKED HIM TO BRING THE CAR HERE.

THIS IS ACTUALLY MORE FUN THAN DYNO'ING A BIG POWER CAR.

(PAT)>> I FEEL SAFER BUT NOT REALLY. JUST FOR FUN, LET'S SEE WHAT THIS ONE HAS LEFT IN IT.

(MIKE)>> ALRIGHT, HERE WE GO.

(PAT)>> WE'LL MAKE THE PULL FROM 2,000 TO 3,800 AND HOPE WE CAN MAKE IT THERE. THIS ISN'T THE ORIGINAL 225 ENGINE. IT WAS REPLACED WITH A 95 HORSEPOWER 1975 MODEL IN THE '80'S, AND IT'S SEEN A LOT OF MILES SINCE, MAKING THIS DUSTER THE PERFECT HOME FOR OUR LEANING TOWER OF POWER. I THINK WE'RE THERE. AT A WHOPPING 64 MILES PER HOUR IT MADE JUST OVER 70 HORSEPOWER, AND THE GRAFPH TELLS THE STORY.

(MIKE)>> WE'RE NOT LAUGHING AT IT CAUSE THIS WAS A STAPLE OF ECONOMICAL PERFORMANCE BACK IN THE DAY. SO TO GET KEN BACK IN RELIABLE CRUISING STATUS WE'LL BE UPGRADING THE COOLING SYSTEM FROM SUMMIT RACING, A DRUM TO DISC BRAKE CONVERSION KIT FROM CLASSIC PERFORMANCE PRODUCTS, ALL NEW STEERING LINKS, SHOCKS, AND MOUNTS FROM ROCK AUTO, A 3.21 RING AND PINION FROM YUKON GEAR AND AXLE, AND ADCO SWAY BARS FOR BETTER HANDLING. FROM THE TOP WE'LL START REMOVING EVERYTHING WE CAN WITHOUT DRAINING ANY FLUIDS YET. THIS WILL INCLUDE THE SINGLE BARREL CARBURETOR, INTAKE MANIFOLD, AND THE CAST IRON EXHAUST MANIFOLD.

THIS DUSTY WAS FACTORY EQUIPPED WITH AIR CONDITIONING, AND IT'S GOING BACK THAT WAY.

NOW IT'S BEEN OUT OF SERVICE FOR QUITE A FEW YEARS, SO THERE IS NO REFRIGERANT IN THE LINES, ALLOWING US TO REMOVE THEM WITHOUT AN EVAC SYSTEM. NOW WE CAN REMOVE THE MASSIVE STARTER, AND USING OUR MATCO EVAC CANISTER, DRAIN AS MUCH POWER

STEERING FLUID OUT OF THE RESERVOIR AS POSSIBLE. THE SAME GOES FOR THE MASTER CYLINDER.

(PAT)>> NOW WE CAN LOOSEN THE ALTERNATOR TO REMOVE THE BELT. THE UNBOLT THE MECHANICAL FAN AND REMOVE IT WITH THE WATER PUMP PULLEY. NOW WE HAVE ACCESS TO THE FASTENERS THAT HOLD THE

A/C COMPRESSOR BRACKET IN PLACE SO THE WHOLE

ASSEMBLY GOES AS WELL. FROM UNDERNEATH WE CAN DRAIN THE COOLANT AND THE ENGINE OIL, REMOVE THE TRANSMISSION LINKAGE, UNBOLT THE TORQUE CONVERTER FROM THE FLEX PLATE, REMOVE THE TRANSMISSION COOLER LINES, AND GET AS MUCH FLUID OUT OF THEM AS WE CAN.

(MIKE)>> NOW THE DRIVE SHAFT CAN BE PULLED AND THE BELL HOUSING BOLTS SO WE CAN DROP THE TRANSMISSION. THIS IS A 904 THAT'S GETTING REPLACED WITH A REMANUFACTURED UNIT. WITH THE ENGINE MOUNT NUTS REMOVED.

(PAT)>> YOU'RE GOOD ON THE BACK.

(MIKE)>> WE CAN HOIST THIS 225 OUT OF THE CAR TO MAKE

WAY FOR THE NEW BULLET.

(MIKE)>> WE'RE BACK AND BEFORE THE NEW ENGINE AND TRANS GOES IN, WE HAVE PLENTY TO DO UNDERNEATH. WHEN'S THE LAST TIME YOU POPPED OFF A HUB CAP?

LOOKS LIKE IT'S BEEN A WHILE FOR KEN TOO. THE FRONT WHEELS ARE 14 INCH IN DIAMETER AND CANNOT BE USED WITH OUR FRONT DISC BRAKE UPGRADE SINCE THEY REQUIRE A 15 INCH WHEEL FOR CLEARANCE. SO AWAY THEY GO. THE NASTY, DIRTY DRUM BRAKE ASSEMBLIES ARE THE NEXT PIECES TO COME OFF. NOW THE EASIEST WAY IS TO SEPARATE THE UPPER AND LOWER BALL JOINTS AND REMOVE THE WHOLE SET UP AS AN ASSEMBLY. FOLLOWED BY THE UPPER CONTROL ARMS AND THE SHOCK ABSORBERS. WE'RE ALSO GOING TO REPLACE THE BUSHINGS IN THE STRUT RODS SO THEY CAN BE REMOVED AS WELL. THIS REQUIRES REMOVING THE TORSION BAR BY LOOSENING THE NUT UP FRONT AND REMOVING THE RETAINING CLIP AT THE BACK. NOW THE BAR CAN BE PUSHED REARWARD SO WE CAN REMOVE THE LOWER CONTROL ARM ASSEMBLY.

(PAT)>> SINCE THE UPPER CONTROL ARMS ARE SHINY NEW, WE'LL CLEAN AND PAINT THE LOWERS TO MATCH THEM WITH VHT'S BLACK EPOXY PAINT, WHICH IS RUST AND SALT RESISTANT. AS THEY'RE DRYING, WE CAN PUT IN THE UPPERS FROM CLASSIC PERFORMANCE THAT ARE A DIRECT REPLACEMENT AND COME READY TO BOLT IN WITH NEW BUSHINGS AND BALL JOINTS ALREADY INSTALLED. NEW BUSHINGS AND WASHERS ARE GOING ON THE STRUT RODS TO ELIMINATE MOVEMENT THAT CAN EFFECT THE CAR'S ALIGNMENT WHILE DRIVING. ON THE OTHER SIDE OF THE STRUT ROD WE CAN ATTACH THE FRESHENED UP LOWER CONTROL ARM AS IT SLIDES THROUGH THE KMEMBER. AND WITH THE LOWER ARM FORCED DOWN WITH A PRY BAR, WE CAN REINSTALL THE ORIGINAL TORSION BAR AND RETAIN IT OUT BACK WITH THE FACTORY CLIP.

(MIKE)>> THIS DRUM TO DISC BRAKE CONVERSION FROM

CLASSIC PERFORMANCE FITS '63 THROUGH '76 "B" AND "E" BODY MOPARS. NOW IT COMES WITH AN 11 INCH VENTED ROTOR THAT HAS A FIVE ON FOUR AND A HALF INCH BOLT CIRCLE. NOW YOU ALSO GET A POWER ASSISTED BOOSTER, MASTER CYLINDER, AND PROPORTIONING VALVE ALREADY PREASSEMBLED. NOW THE KIT ALSO INCLUDES BRAND NEW SPINDLES, STEERING LINKS, CALIPERS, BRAKE PADS, AND THE HARDWARE FOR AN EASY INSTALLATION. THE SPINDLES MOUNT TO THE LOWER CONTROL ARMS FIRST USING THE SUPPLIED CASTLE NUT AND COTTER PIN. NOW THE UPPER CONTROL ARM CAN ATTACH TO THE SPINDLE THE SAME WAY. WITH THE BEARINGS AND SPINDLE GREASED, WE CAN SLIDE THE ROTOR INTO PLACE. THE SPINDLE NUT NEEDS TO BE FINGER TIGHTENED AS YOU ROTATE THE ROTOR. NOW ONCE ALL THE PLAY IS OUT OF THE BEARINGS, I'LL PRELOAD IT TO THE NEXT SLOT THE COTTER PIN CAN DROP INTO SINCE THE BEARINGS ARE NEW. THE NEW PAD CAN GO IN PLACE, FOLLOWED BY THE SINGLE PISTON CALIPER WITH THE OTHER PAD INSIDE OF IT. THESE CLIPS ARE ALL THAT RETAIN IT. SOMETHING ELSE KEN NEEDS BESIDES AN ENGINE ARE NEW SHOCKS. NOW THESE ARE KYB GAS ADJUSTS WE GOT IN FROM ROCK AUTO DOT COM. REPLACING THE BRAKE LINES IS A MUST FOR A CAR THIS OLD. THESE CAME WITH THE BRAKE CONVERSION.

(PAT)>> WITH NEW BRAKES AND SUSPENSION, WE'RE GONNA PUT THE FIRMNESS BACK IN THE STEERING WHEEL AS WELL. WE'RE GONNA REPLACE EVERYTHING IN IT THAT HAS A BALL JOINT BECAUSE FRANKLY WE KNOW THEY'RE ALL WORN OUT. AND THAT'LL INCLUDE A NEW PITMAN ARM, IDLER ARM, AND NEW INNER AND OUTER TIE ROD ENDS WITH NEW ADJUSTING SLEEVES. THE FIRST THING TO GO IS THE WORN OUT IDLER ARM. WE'LL USE OUR MATCO AIR HAMMER AND BALL JOINT

SEPARATOR TO REMOVE IT. THE NEW ONE CAN GO BACK IN ITS PLACE AND TIGHTEN DOWN. THE PITMAN ARM JOINT SEPARATES THE SAME WAY. THEN THE NUT SECURING IT TO THE STEERING BOX GETS REMOVED. WE'LL MAKE SURE TO NOTE THE POSITION ITS IN SO IT GOES BACK THE SAME WAY TO KEEP THE STEERING CENTERED. USING THIS PITMAN ARM REMOVER, WE'LL PULL IT OFF

THE SPLINE SHAFT THAT IT'S WEDGED ON TO, AND REPLACE IT WITH A NEW ONE MAKING SURE IT'S IN THE SAME LOCATION. NOW REATTACH THE DRAG LINK AND FINISH THE STEERING OFF WITH NEW TIE ROD ENDS AND SLEEVES. ALL THE FRONT END NEEDS IS OUR SLANT SIX TO FILL THAT BIG HOLE.

(ANNOUNCER)>> FROM THE STAND TO THE CHASSIS, THE ENGINE'S DROPPING IN AND SO DOES THE OWNER, COMING UP.

(PAT)>> WE'RE BACK AND READY FOR THE TRUE PURPOSE OF THIS CLASSIC ENGINE BUILD, BRINGING IT TO LIFE IN A CLASSIC, ERA CORRECT CRUISER.

WITH ITS NEW MOUNTS AND THIS DUSTER'S OIL PAN AND PICK UP INSTALLED, IT'S TIME TO DROP IT IN. I DON'T KNOW?

(MIKE)>> NICE, NICE!

(PAT)>> I'M GOOD RIGHT HERE.

HOW'S THAT OTHER SIDE?

OH, OH, SOMETHING HAPPENED!

(MIKE)>> IT'S IN!

(PAT)>> YES, YES, YES!

(MIKE)>> LOOK AT THAT WITH THE HEADER ON.

(PAT)>> NICE JOB.

(MIKE)>> VERY CLEAN LOOKING. POWERTRAIN PRODUCTS SENT US THIS REMANED 904 AUTOMATIC TRANSMISSION. NOW THEIR REBUILD PROCESS IS STRAIGHT FORWARD, KEEP THE ORIGINAL PARTS TOGETHER LIKE THE VALVE

BODY, CASE, AND HARDWARE LIKE IT LEFT THE FACTORY FOR A MORE RELIABLE UNIT. NOW ONCE ASSEMBLED, EACH ONE IS TESTED ON THEIR CUSTOM DYNOS THAT APPLY FORCE TO REPLICATE REAL WORLD DRIVING CONDITIONS SO THAT THEY KNOW IT'S A

SOLID UNIT BEFORE IT LEAVES THEIR FACILITY. THEY ALSO TRIPLE CHECK ALL THE THREADS AND FASTENERS TO INSURE PROPER TORQUE SPECS ARE ACHIEVED. PLUS THEY SUPPLIED THE TORQUE CONVERTER TO MAKE THIS A PACKAGE DEAL. A 318 DODGE RAM START THAT'S SMALLER AND SPINS FASTER WILL FIRE UP THE SLANTY. NOW THE BOOSTER AND MASTER CYLINDER ARE THE FINAL PIECES FOR THE FRONT BRAKES. THE ASSEMBLY BOLTS TO THE FACTORY MASTER CYLINDER STUDS. IT'S ALSO GETTING A NEW POWER STEERING PUMP AND A/C COMPRESSOR FROM ROCK AUTO. VOLTAGE WILL BE SUPPLIED TO THE BATTERY WITH A NEW ALTERNATOR FROM ROCK AUTO AS WELL. NOW THE FRESHLY PAINTED FAN CAN GO ON, AND TO DRIVE ALL THIS THREE NEW VBELTS. TO KEEP THE SLANT SIX COOL, THIS REPLACEMENT RADIATOR THAT'S A DIRECT FIT FROM ROCK AUTO. IT'S ALSO GETTING NEW HOSES.

IN FACT, WE FINISHED OFF THE ENTIRE ENGINE HOOK UP FROM THE WIRING TO THE FUEL LINES AND ON UP TO THIS CLASSIC MOPAR AIR CLEANER. WE TORE THE REAR END DOWN AS WELL, REPLACING THE 2.76 RING AND PINION WITH A 3.21 FROM YUKON GEAR AND AXLE. THE LEAF SPRINGS HAD LITTLE SPRING LEFT IN THEM. SO IT'S GETTING THESE FROM CLASSIC INDUSTRIES. AND PAIR THEM UP WITH NEW SHOCKS AS WELL.

FOR ROLLERS, COKER TIRE MOPAR RALLY WHEELS WITH TRIM RINGS AND CENTER CAPS, WRAPPED WITH BFG SILVER TOWN REDLINE RADIALS MADE BY THEM AS WELL, WHICH WILL COMPLIMENT THE CAR'S COLOR.

THE EXHAUST IS MADE FROM SCRATCH USING MAGNAFLOW'S TWO AND A HALF INCH STAINLESS PIPE AND AN 18 INCH STRAIGHT THROUGH MUFFLER FINISHED OFF WITH A TURN DOWN. AT THIS POINT THIS PROJECT IS DONE. AND JUST IN TIME!

(KEN)>> I FEEL LIKE A KID, I FEEL LIKE A KID AT CHRISTMAS.

(MIKE)>> WELL THE GOOD THING IS YOU CAN PULL IT OUT OF YOUR DUSTER, PUT IT IN A TRACTOR, AND PUT IT BACK IN THE DUSTER, MULTIPURPOSE!

(KEN)>> HOW MANY HORSE DO YOU THINK ITS PULLING?

(MIKE)>> WE'RE ABOUT TO FIND OUT.

(KEN)>> THOSE RED STRIPE TIRES ARE REALLY MAKING THAT PAINT JOB POP!

(MIKE)>> ALRIGHT KEN, WE DIDN'T TELL YOU, BUT WHEN YOU DROPPED THE CAR OFF WE WENT AHEAD AND PUT IT ON THE DYNO TO GET A BASE LINE. IT ONLY MADE 71 HORSEPOWER.

(KEN)>> ALRIGHT, AND HOW WAS THAT FOR

A MOTOR THAT AGE?

(MIKE)>> I THINK I HAVE A LAWNMOWER THAT MAKES A LITTLE MORE.

WE'RE TAKING THIS ONE TO A SAFE 4,500 RPM. LOOK AT THAT, 125 HORSEPOWER, 161 FOOT POUNDS OF TORQUE. WE'RE NOT DONE!

(KEN)>> OH WE'RE NOT?

(MIKE)>> NO, WE'RE GONNA PULL A LITTLE MORE OUT OF IT.

(KEN)>> OH REALLY!

(MIKE)>> I'LL MAKE A TIMING CHANGE. TWO MORE DEGREES OF INITIAL TIMING FOR A TOTAL OF SIX. 129 AND 164, PICKED UP THREE FOOT POUNDS AND FOUR HORSEPOWER.

(KEN)>> THAT'S IMPRESSIVE!

(MIKE)>> ONE LAST RUN WITH TWO MORE INITIAL DEGREES FOR A TOTAL OF EIGHT. HOW DO YOU LIKE THAT, 132, 170?

(KEN)>> THAT IS MARVELOUS.

(MIKE)>> TWO DEGREES PICKED IT UP THREE HORSEPOWER AND SIX FOOT POUNDS.

(KEN)>> AND YOU JUST CAN'T GET USED TO HEARING THAT ROAR. I CAN SEE IT ROLLING DOWN THE ROAD, JUST ZIPPING.

(MIKE)>> AND NOW HE CAN WITH ALMOST TWICE THE POWER HE STARTED WITH. HATS OFF TO KEN FOR KEEPING THE LEGEND OF THE SLANT SIX ALIVE!

(PAT)>> AN IMPORTANT BUT OFTEN OVERLOOKED ASPECT OF

ENGINE BUILDING IS BALANCING, AND THERE'S TWO TYPES OF BALANCING THAT ARE DONE TO YOUR POWER PLANT WHEN YOU TAKE IT TO A MACHINE SHOP. THE FIRST IS DYNAMIC, MEANING SPINNING THE CRANK SHAFT WITH BOB WEIGHTS ATTACHED TO IT ON A MACHINE TO MEASURE THE BALANCE TOLERANCE. THE OTHER IS STATIC, MEANING WEIGHING ALL THE COMPONENTS AND MAKING THEM WEIGH WITHIN A CERTAIN AMOUNT. SINCE INLINE CRANKS DON'T REQUIRE A BOB WEIGHT TO

GET SPIN BALANCED, THE PARTS DON'T HAVE TO GO WITH THE CRANK TO THE MACHINE SHOP. MIKE AND I ARE GOING TO SHOW YOU HOW TO STATIC BALANCE PISTONS AND RODS YOURSELF WITH A FEW THINGS YOU MOST LIKELY HAVE LYING AROUND, LIKE A BELT SANDER, A DIE GRINDER WITH A FEW CARTRIDGE ROLLS AND CARBIDES, PLUS SOMETHING YOU'LL ACTUALLY HAVE TO BUY, LIKE THIS AFFORDABLE GOODSON BALANCING SETUP.

(MIKE)>> NOW DOING THIS YOURSELF IS GOING TO SAVE YOU MONEY AT THE MACHINE SHOP ON ANY INLINE ENGINE SINCE THEY WON'T HAVE TO TAKE THE TIME TO BALANCE THESE PARTS THEMSELVES. NOW WEIGHT MATCHING ALL OF THESE COMPONENTS IS GOING TO HELP THE ENGINE TO RUN SMOOTHER AND LAST LONGER NO MATTER THE APPLICATION. WITH OUR GOODSON GRAM SCALE FIRED UP, WE'LL

START BY WEIGHING THE PISTONS. BE SURE TO PRENUMBER THEM SO THAT YOU CAN KEEP TRACK OF THE WEIGHTS TO AVOID CONFUSION. NOW WHAT WE'RE LOOKING FOR ARE THE LIGHTEST ONES IN THE SET. NOW WE RECORDED THE WEIGHT OF EACH PISTON AND FOUND THE LIGHTEST ONES, WHICH COME IN AT 604 GRAMS. THE GOAL IS TO GET THEM ALL TO WEIGH WITHIN ONE GRAM OF EACH OTHER. SO THE NEXT STEP IS TO SET UP YOUR DIE GRINDER TO START REMOVING SOME MATERIAL. NOW MAKE SURE YOU ALSO HAVE YOUR SAFETY GLASSES ON FOR THIS BECAUSE YOU DON'T WANT THE ALUMINUM IN YOUR EYES.

(PAT)>> STARTING WITH THE HEAVIEST, WHICH WAS PONE AT 607 GRAMS, THE OBJECT IS TO LIGHTLY GRIND AROUND THE THICKEST PART OF THE PIN BOSS AREA, WHICH REMOVES WEIGHT. MAKE SURE TO REPEATEDLY CHECK IT ON THE SCALE DURING THIS PROCESS. SO FAR WE'VE REMOVED ONE GRAM. SO TWO MORE HAVE TO COME OFF TO REACH THE LIGHTEST PISTON WEIGHT OF 604. THIS IS ONE OF THOSE OPERATIONS WHERE YOU NEED TO TAKE YOUR TIME AND NOT GET TOO AGGRESSIVE.

IT'S EASY TO TAKE OUT TOO MUCH AND HAVE TO START THE WHOLE PROCESS OVER AGAIN. NOW IT GOES BACK TO THE SCALE AND THE MAGIC NUMBER HAS BEEN MET. SWITCHING TO A CARTRIDGE ROLL, WE CAN CLEAN UP ANY ROUGH EDGES THAT THE BURR CREATED AND THAT WRAPS UP THE PISTONS. WE ONLY HAD TO REMOVE WEIGHT OUT OF FOUR PISTONS BECAUSE TWO OF THEM WERE AT THE LOWEST WEIGHT OF 604. TYPICALLY PISTONS WILL WEIGH WITHIN FOUR GRAMS OF EACH OTHER, WHICH IS FINE FOR PRODUCTION ENGINES. WITH OUR CAPABILITIES AND OUR SET UP HERE, WHY NOT

MAKE THEM WEIGH ALL THE SAME LIKE A RACE ENGINE.

(MIKE)>> NEXT UP ARE THE RODS. NOW BOTH ENDS HAVE TO BE BALANCED BECAUSE THE SMALL END RECIPROCATES AND THE BIG END ROTATES. SO THEY EFFECT THE TOTAL BALANCE DIFFERENTLY. NOW THAT'S WHERE THE GOODSON ROD

FIXTURE COMES INTO PLAY. WE HAVE TO WEIGH THE BIG ENDS AND THE SMALL ENDS, AND FIND THE LIGHTEST ONES JUST LIKE THE PISTONS. WE'LL GO AHEAD AND START WITH THE BIG END. ACCURACY AND REPEATABILITY ARE KEY WHEN

USING THE FIXTURE. NOW I'LL PLACE THE ROD WITH THE BEARING TANGS FACING DOWN. NOW MAKE SURE THE ROD'S BEAM IS LEVEL AND IT'S NOT

BINDING IN THE FIXTURE. IF IT IS, THE READING WILL BE INACCURATE. ROD ONE'S BIG END WEIGHS 424 GRAMS. THE LIGHTEST BIG END IS ROD FOUR, WHICH IS 421. MATERIAL MUST BE REMOVED IN A SAFE SPOT ON THESE AS WELL. IN THIS CASE, THERE IS A DISTINCT BALANCE PAD ON EACH END. USING OUR DAKE BELT SANDER, WE'LL CAREFULLY SAND A LITTLE AT A TIME OFF THE HEAVIEST BIG END, REPEATEDLY CHECKING OUR PROGRESS TO MAKE SURE WE DON'T OVER DO IT. NOW I'M GONNA SET THE FIXTURE UP TO DO THE SAME PROCEDURE TO THE SMALL END OF THE ROD. WE JUST NEED TO MOVE THE BIG END BUSHING TO THE OTHER SIDE AND PRACTICE THE SAME REPEATABILITY AND ACCURACY AS BEFORE.

(PAT)>> THE LIGHTEST SMALL ENDS WERE 180 GRAMS AND THERE WERE TWO OF THEM. THE HEAVIEST WAS 182.

THAT'S A CLOSE RANGE FOR FACTORY PRODUCTION PIECES. NOW I'LL MATCH THE WEIGHTS TO THE LIGHTEST, THE SAME WAY AS THE BIG END ON THE BELT SANDER. WITH THE SMALL END WEIGHTS AT 180 GRAMS AND THE BIG END AT 421 GRAMS, ALL SAID AND DONE, THE ROD SHOULD WEIGH 601 GRAMS. AND HERE'S HOW TO CONFIRM THAT. YOU PUT THE ROD DIRECTLY ON THE SCALE AND THE MAGIC NUMBER WILL POP RIGHT UP, JOB WELL DONE. BALANCING THE PISTONS AND RODS YOURSELF IS ANOTHER TASK THAT YOU CAN ADD TO YOUR ENGINE BUILDING SKILL SET. PLUS WITH A SET UP LIKE THIS, YOU CAN PAY IT OFF AND EVEN PUT A LITTLE MONEY IN YOUR POCKET HELPING YOUR BUDDIES OUT TOO.

(MIKE)>> SO REMEMBER, KEEP YOUR BALANCE AND MAY THE SLANT BE WITH YOU. WE'LL SEE YOU NEXT TIME.