Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

Hooker Headers

Headers, Blackheart, Full-Length, 1 7/8 in. Primary, Stainless Steel, Natural, Ford, 5.0L, Pair

Hooker Headers

Motor Mounts, Engine Swap, Frame Pad Style, Steel, Zinc Plated, Buick, Chevy, Pontiac, Small Block LS, Pair

QA1

507 Aluminum Stocker Star Shock, Double Adjustable, GM A-Body, 70-81 F-Body and 63-82 Corvette Stock Mount Shocks

Yukon Gear & Axle

Differential Carrier, Grizzly Locker, Chromium Alloy Steel, 30-spline, Rear, GM 8.5 in., GM 8.6 in., Each

Yukon Gear & Axle

Gear, Ring and Pinion, 3.23:1 Ratio, 1.625 in. Pinion, 30 Spline, 8.500 in. Ring Gear, GM 8.5 in., Set

Kimberly-Clark Professional

Scott Heavy Duty Shop Towels, Blue, 60CT Roll

Matco Tools

4000LB Engine Hoist

Matco Tools

TJ1000A - 1000 LB. Telescopic Transmission Jack

The Industrial Depot

The Industrial Depot - Fasteners, Hardware, and Shop Supplies

WD-40 Specialist

WD-40 EZ-Reach Flexible Straw

Episode Transcript

(MIKE)>> WELCOME

TO ENGINE POWER. TODAY WE START

ANOTHER PROJECT. IT'S A CHEVY BUT NOT ONE

YOU'D EXPECT TO SEE IN HERE. MEET GRAY HAIR, WHITE

KNUCKLE, AN OLDER COUPLE'S CAR WE HAD

TO HAVE FOR THIS OFF THE WALL BUILD.

IT'S ONE OF THE CLEANEST '93 CAPRICE CLASSICS WE HAVE SEEN IN A LONG TIME. THIS IS A FULL FRAME CAR WITH AN LOTHREE 305 BETWEEN ITS FENDERS. IT PRODUCES 170 HORSEPOWER AND A WIG SNATCHING 255 POUND FEET OF TORQUE. IT HAS AN IRON BLOCK AND CYLINDER HEADS, WHICH ARE TOPPED OFF WITH TBI INJECTION. THE INTERIOR HAS A DRIVE IN MOVIES BEST LAYOUT. A BIG FRONT BENCH SEAT, TILT WHEEL, AND PLENTY OF ROOM OUT BACK FOR 100 CHIHUAHUAS SPORTING THEIR LITTLE BOWS. THIS CAR'S PURPOSE FROM DAY ONE WAS TO BE A

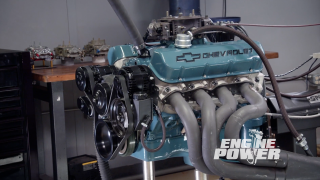

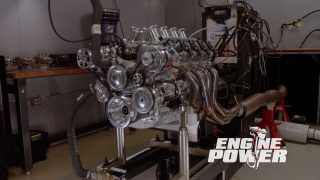

CRUISER FOR LET'S JUST SAY SENIOR CITIZENS. WITH ITS FOURL-60 AUTOMATIC TRANSMISSION AND 2.56 REAR GEAR IT WAS ALL ABOUT FUEL ECONOMY AND COMFORTABLY BLOCKING THE FAST LANE ON THE INTERSTATE. HERE'S WHERE THAT OFF THE WALL BUILD COMMENT COMES INTO PLAY. REMEMBER THIS LSA? IT'S THE ONE PAT AND I BUILT WITH A COUPLE OF GUYS FROM THE SCHOOL OF AUTOMOTIVE MACHINISTS. NOW IT PACKS 427 CUBIC INCHES AND RUNS ON 93 OCTANE PUMP GAS. NOW IT MAKES 816 HORSEPOWER, WHICH IS OVER FOUR TIMES THE AMOUNT OF THAT 305 THAT'S IN THE CAPRICE NOW. NOW AS FAR AS TORQUE, THIS THING MAKES ALMOST AS MUCH AS A NEW CUMMINS TURBO DIESEL WITH 797 POUND FEET OF TORQUE.

(PAT)>> THAT ENGINE NEEDS TO BE BACKED WITH COMPONENTS THAT WILL HANDLE THE ROWDINESS WHEN THE LOUD PEDAL HITS THE FLOOR, AND IT STARTS WITH THIS SIX SPEED AUTOMATIC TRANSMISSION THAT'S RATED

TO HANDLE 850 HORSEPOWER. YUKON GEAR AND AXLE SUPPLIED A FULL TILT REBUILD FOR THE REAR END, WHICH WE SOURCED FROM A DIFFERENT CAPRICE. AND THE REAR SUSPENSION IS SIMPLE YET EFFECTIVE WITH A BUNCH OF QUALITY AFTERMARKET COMPONENTS FROM SUMMIT RACING, BUT BEFORE WE CAN PUT ALL THESE COOL PARTS IN THERE'S A LOT OF WORK THAT'S GOT TO BE DONE AND IT STARTS WITH THE TEAR DOWN.

WE'RE STARTING AT THE TOP WITH THE UPPER FAN SHROUD,

FAN, AND AIR BOX. OH TROUBLE! THERE'S A LOT OF SMALL STUFF THAT NEEDS TO BE DISCONNECTED AND IT'S PACKED IN HERE. A LOT OF IT IS NOT NEEDED BUT IT'S STILL NICE TO SALVAGE ALL WE CAN. TO THE BOTTOM WE GO. YOU'VE SEEN US PULL ENGINES AND TRANS FROM LATE MODEL CARS AND THEY CAME OUT THE BOTTOM. NOT THIS FULL FRAME CRUISER. WE'LL REMOVE THE TRANS FROM DOWN HERE. ALRIGHT ONE TRANSMICHIGAN REMOVED! AND THEN GO BACK UP TOP TO REMOVE THE ENGINE. AS FAR AS WE KNOW EVERYTHING IS DISCONNECTED. SO OUR MATCO ENGINE LIFT CAN GET TO WORK.

WITH A LITTLE LIFT, A LITTLE SHAKE, THIS 305 IS COMING OUT AND NEVER RETURNING. AND WE ARE CLEAR! I WONDER HOW MANY TIMES THIS GOT DRIVEN TO BINGO?

NOW A LITTLE CLEAN UP JOB WITH THE PRESSURE WASHER. ALL IT'S DOING IS KNOCKING OUT SOME DIRT. I DON'T THINK THIS CAR EVER HAD A FLUID LEAK. WITH IT CLEAN ENOUGH WE'RE CHANGING OUR ATTENTION TO THE REAR END.

THIS IS A SEVEN POINT FIVE INCH REAR, AND IT WON'T HOLD UP TO OUR LSA'S POWER. SO IT'S GOT TO GO. PULLING IT IS SIMPLE. UNBOLT THE SHOCKS, REMOVE THE COIL SPRINGS, UNDO THE FOUR FASTENERS HOLDING THE UPPER AND LOWER CONTROL ARMS TO THE FRAME. NOW SUPPORT IT, PULL THE BOLTS, AND RAISE THE CAR AWAY FROM IT. DON'T WORRY, WE DIDN'T FORGET THE BRAKE ABS LINES. KNOWING THAT THIS STOCK SEVEN POINT FIVE INCH AXLE WOULDN'T LAST LONG FOR WHAT WE'RE DOING WITH THIS BUILD, WE SOURCED A TAKE OUT EIGHT POINT FIVE INCH

10 BOLT REAR END. THE EIGHT POINT FIVE REFERS TO THE DIAMETER OF THE RING GEAR, AND THAT REQUIRES A PHYSICALLY LARGER HOUSING THAT IS MORE CAPABLE OF HANDLING THE ADDITIONAL POWER. THIS AXLE IS A DIRECT BOLT IN FOR OUR CAPRICE WITH ALL OF THE SUSPENSION BRACKETS, BRAKE LINE MOUNTS, AND EVEN THE ABS SENSOR ALL IN THE SAME SPOT. BUT BEFORE WE DO THAT WE'RE GONNA REBUILD AND UPGRADE ALL THE INTERNALS. WE ONLY HAVE TO USE THE HOUSING ITSELF. SO EVERYTHING GETS REMOVED TO GET CLEANED UP FOR NEW PARTS. FIRST I'LL POP THE REAR COVER TO TAKE A LOOK AND SEE THAT THE FLUID IS ALREADY DRAINED. NEXT ALL THE OLD BRAKE STUFF CAN COME OFF AS WELL. AN IMPALA SS HAS REAR DISCS. THIS HOUSING IS FROM A HEAVY DUTY CAPRICE, LIKE A TAXI, AND IS SETUP WITH DRUM BRAKES. THESE ARE A "C" CLIP STYLE AXLE, SO THE PIN CAN BE TAKEN OUT, THE AXLES PUSHED INWARD, AND THE "C" CLIPS CAN BE REMOVED. THAT ALLOWS THE AXLES TO SLIDE RIGHT OUT. HERE'S A LITTLE TIP. USE A STAMP OR A CHISEL TO MARK THE ORIENTATION OF THE DIFFERENTIAL CAPS. NOW LOOSEN AND REMOVE THE CAPS AND THE DIFF AND RING GEAR IS READY TO COME OUT. BE SURE TO KEEP TRACK OF THE SHIM POSITIONS VERY CAREFULLY. THIS WILL HELP GET THINGS SETUP QUICKER ON REASSEMBLY.

THE PINION NUT IS REMOVED AT THIS TIME AND THE PINION COMES RIGHT OUT. FINALLY I'LL CLEAN OUT THE WHOLE THING WITH DEGREASER, SCOTT SHOP TOWELS, AND SOME ELBOW GREASE. WE'LL GET TO THE REBUILD AFTER THE BREAK.

(MIKE)>> WE'RE BACK, AND JUST LIKE PAT TOLD YOU, THE REBUILD STARTS NOW. YUKON GEAR AND AXLE IS OUR GO TO SOURCE FOR QUALITY AXLE COMPONENTS. NOW THEIR INVENTORY WILL ABSOLUTELY BLOW YOUR MIND. WHETHER YOU'VE GOT A PAVEMENT POUNDER OR A FULL BLOWN TRAIL RIG, THEY'VE GOT YOU COVERED. NOW WE'RE GONNA BUILD THAT EIGHT AND A HALF INCH 10 BOLT REAR END WITH THEIR GRIZZLY LOCKER AS THE CENTER PIECE. THIS ONE ACCEPTS 30 SPLINE AXLES AND COMES WITH AN OUTSTANDING WARRANTY. NOW DUE TO THE TORQUE CURVE OUR LSA PRODUCES WE'RE USING A 3.23 RING AND PINION SET, WHICH IS GONNA BE VERY MELLOW.

NOW THIS IS A TWO CUT DESIGN AND IT'S GUARANTEED TO RUN COOLER AND QUIETER THAN OTHER SETS ON THE MARKET. NOW AS FAR AS THE INSTALL KIT GOES IT SPEAKS FOR ITSELF. EVERYTHING YOU NEED TO GET THOSE COMPONENTS IN THE HOUSING. NOW WE'RE GONNA START BY GETTING THE PINION SETUP. A PRESS IS THE BEST THING TO USE FOR THIS. STAY AWAY FROM A HAMMER AND CHISEL. THIS SHIM IS FROM THE ORIGINAL PINION. IT'S ALWAYS A GOOD STARTING POINT SINCE IT CAME OUT OF THE SAME HOUSING. NOW THE BEARING IS PLACED OVER THE PINION GEAR, FOLLOWED BY A PIECE OF PIPE, AND A PIECE OF STEEL TO PRESS AGAINST. START APPLYING PRESSURE TO DRIVE THE BEARING ALL THE WAY TO THE SHIM. WHILE WE'RE HERE WE'LL ALSO PRESS THE

BEARINGS ON THE CARRIER. THERE ARE NO SHIMS USED HERE. THE PINION BEARING RACE IS READY TO GO IN THE HOUSING. ALWAYS USE A RACE INSTALLER LIKE THIS TO GET IT IN. LISTEN AS THE RACE IS TAPPED IN. YOU CAN HEAR AN AUDIBLE CHANGE WHEN IT IS SEATED.

WITH THE HOUSING ROTATED 180 DEGREES WE CAN INSTALL THE OTHER RACE FOR THE PINION. IT GOES IN THE SAME WAY. NOW THE PINION GEAR CAN BE PLACED IN THE HOUSING, THE HOUSING ROTATED UP, AND PAT WILL DROP IN THE CRUSH SLEEVE AND BEARING, ALIGN THE YOKE WITH THE GEAR'S SPLINES, AND USE THE NUT TO RUN IT DOWN. GETTING THE CRUSH SLEEVE TO ACTUALLY

CRUSH CAN BE A CHORE. JUST KEEP AT IT. WITH THE SLACK OUT, I'LL USE A BEAM TYPE TORQUE WRENCH TO CHECK THE BEARING'S PRELOAD. 16 TO 19 INCH POUNDS IS THE TARGET. IT'S NOT ENOUGH YET. A LITTLE MORE WANG DANG WITH THE IMPACT AND ANOTHER CHECK. 15, 16, IT'S PERFECT! THIS IS ALL SETUP WORK AND NOT FINAL ASSEMBLY. THE RING GEAR IS NEXT.

NEVER USE THE BOLTS TO PULL IT ON THE CARRIER. YOU'LL RISK STRIPPING THE THREADS OUT OF THE GEAR. I USUALLY PUT THESE IN AN OVEN SO THAT ITS JUST EVEN HEAT.

THE NEXT BEST THING IS A HEAT GUN. DON'T USE A TORCH. USING A TORCH WILL DESTROY THE HEAT TREAT OF THE GEAR.

(PAT)>> WHENEVER YOU'RE READY.

(MIKE)>> I'M READY. WITH OUR TARGET OF 200 DEGREES REACHED WE WILL PULL THE GEAR ONTO THE CARRIER. NOTICE HOW THE GEAR IS FULLY SEATED ALREADY. FINAL TORQUE WILL BE 60 POUND FEET.

(PAT)>> WITH THE PASSENGER SIDE SHIMS IN PLACE, THE GRIZZLY LOCKER GETS DROPPED IN. NOW THE DRIVER'S SIDE SHIMS CAN BE INSTALLED. THIS IS A SNUG FIT TO ENSURE THE BEARINGS ARE SLIGHTLY PRELOADED. USING A BRASS DRIVE, SEAT THE SHIMS. NOW THE ORIGINAL CAPS CAN GO ON IN THEIR MARKED LOCATIONS, AND TORQUED TO 65 POUND FEET. THE GEAR NOISE YOU HEARD IS CALLED BACKLASH. THE SPEC FOR IT SHOULD BE BETWEEN THREE AND SIX THOUSANDTHS. A DIAL INDICATOR ALLOWS US TO MEASURE THE BACKLASH ACCORDINGLY. THE GAUGE IS PLACED ON A SINGLE TOOTH OF THE RING GEAR. NOW ZERO IT OUT.

THE GAUGE SHOWS WE HAVE SIX THOUSANDTHS, SO WE ARE IN THE CORRECT RANGE. HERE'S A CLOSE UP OF WHAT SIX THOUSANDTHS OF BACKLASH LOOKS LIKE. GEAR MARKING COMPOUND IS USED TO CHECK THE PATTERN, OR GEAR MESH, BETWEEN THE RING AND PINION. NOW TURN THE PINION AND HOLD A HAND ON THE DIFF FOR SOME RESISTANCE. THIS WILL ALLOW THE MARK TO BE VERY VISIBLE ON THE DRIVE SIDE. IT SHOWS WE HAVE AN ACCEPTABLE PATTERN PER THE YUKON INSTRUCTION GUIDE.

WITH THE SETUP COMPLETE IT ALL COMES BACK OUT. SO THE NEW PINION BEARING AND ABS RELUCTOR CAN GO ON. WITH THE PINION BEARING PRELOAD BACK AT 16 INCH POUNDS WITH THE NEW CRUSH SLEEVE, THE DIFF DROPS IN FOR GOOD USING THE SAME SHIM PACKS, AND THE CAPS

GET TORQUED TO 65 POUND FEET. THE GEAR AND DIFF INSTALL IS NOW COMPLETE.

(MIKE)>> THE AXLE BEARINGS CAN GO IN NOW. A FEW TAPS WITH THE HAMMER AND THEY'RE INSTALLED. WE ALWAYS USE A LITTLE SILICONE AROUND THE OUTER SHELL OF THE AXLE SEALS. IT'S AN EASY WAY TO PREVENT A LEAK. WITH A FEW TAPS THEY'RE IN AS WELL. YUKON AXLES ARE A ONE PIECE FORGED 1541-H MATERIAL. THEY ARE 25 PERCENT STRONGER THAN OE AXLES,

WHICH IS A LOT. THE CENTER PIN IS REMOVED FROM THE DIFF, WHICH ALLOWS THE AXLES TO SLIDE IN FAR ENOUGH TO

INSTALL THE "C" CLIPS. USING A MAGNET, POSITION THE CLIP OVER THE GROOVE IN THE AXLE AND PULL IT OUTWARD. THE SAME GOES FOR THE OTHER SIDE. NOW THE PIN IS REINSTALLED AND THE AXLES ARE CAPTURED. YUKON ALSO SENT US THIS DIFFER COVER GASKET, AND A TA PERFORMANCE REAR GIRDLE. IT'S CAST ALUMINUM. ONCE THE COVER IS BOLTED TO THE HOUSING AND TORQUED TO 25 POUND FEET, SCREW THE LOAD BOLT IN BY HAND UNTIL IT MAKES CONTACT WITH THE BEARING CAP, AND TORQUE IT TO FIVE POUND FEET. THE JAM NUT IS RAN DOWN AND TORQUED TO 20 POUND FEET. THIS GIRDLE APPLIES SLIGHT PRESSURE TO THE BEARING CAPS OF THE DIFF, PREVENTING THE CAPS FROM PUSHING BACKWARDS DURING HARD ACCELERATION, CAUSING A FAILURE.

THE FINAL PIECE BEFORE IT GOES IN IS THE ABS SENSOR. WHEN WE COME BACK IT'S GETTING MATED TO THE CAPRICE.

(MIKE)>> WE'RE BACK AND IT'S TIME TO HANG THE REAR END. NOW IT'S NOT GOING BACK IN ITS ORIGINAL LOCATION. WE ORDERED THESE UPPER AND LOWER CONTROL ARMS FROM SUMMIT RACING AND THEY'RE DESIGNED TO POSITION THE REAR AXLE BACK IN THE CENTER OF THE WHEEL WELL. NOW IN CASE YOU DIDN'T NOTICE THE ORIGINAL LOCATION, HERE'S A QUICK LOOK.

(PAT)>> THEY'RE FILLED WITH URETHANE BUSHINGS

AND ZIRK FITTINGS. THE UPPER CONTROL ARMS ARE FULLY ADJUSTABLE FRONT AND REAR, WHICH ALLOWS US TO SET THE PINION ANGLE WHEREVER WE WANT IT. NOW THE FIRST THING TO DO IS PREP THEM. ALWAYS APPLY CHASSIS GREASE TO THE OUTSIDE OF THE BUSHINGS. THIS PREVENTS ANNOYING SQUEAKS AND PREMATURE WEAR AGAINST THE FRAME'S BRACKETS. ANOTHER SMART THING TO DO IS APPLY A GENEROUS AMOUNT OF ANTISEIZE TO THE BOLTS THAT SECURE THEM. THIS PREVENTS THE BOLT FROM CORRODING AGAINST THE INNER SLEEVE OF THE BUSHING OVER TIME, ESPECIALLY IF YOU'RE UP NORTH.

(PAT)>> FOR THIS CAR'S PURPOSE WE NEED A SHOCK

THAT WILL DO IT ALL, MEANING WE WANT TO AUTOCROSS IT, TAKE IT DOWN THE DRAG STRIP, AND HAVE EXCELLENT RIDE QUALITY ON THE STREET. QA ONE, WHO IS A LEADER IN SUSPENSION COMPONENTS, CAME TO THE RESCUE WITH THESE DOUBLE ADJUSTABLES THAT WERE DESIGNED FOR GM "B" BODIES. ONE KNOB IS FRO REBOUND, THE OTHER FOR COMPRESSION. SO WE GET INDEPENDENT ADJUSTMENT FOR BOTH DIRECTIONS OF SHOCK TRAVEL.

(MIKE)>> NOW THE CAR IS LOWERED TO THE REAR END AND THE CONNECTIONS ARE MADE. THE NEW LOWERING SPRINGS, WHICH ARE MUCH SHORTER

THAN STOCK, CAN GO IN NOW, AND THE SHOCKS ATTACH TO THE HOUSING.

(PAT)>> NOW THAT THE WEIGHT IS OUT BACK, WE'RE GONNA GET THE ENGINE AND TRANSMISSION READY TO GO IN. FIVE YEARS AGO WE BUILT A '97 THUNDERBIRD DUBBED "DEEP SLEEP". IT HAD A SIX SPEED AUTO BEHIND A 600 HORSEPOWER

SMALL BLOCK FORD. WELL WE KEPT THE TRANS AROUND AND IT'S GOING IN GRAY HAIR, WHITE KNUCKLE. IN ORDER TO DO SO THIS BELL HOUSING WITH THE FORD PATTERN MUST GO, AND A GM PATTERN GOES IN ITS PLACE.

IT'S MADE BY REED AND IS SFI APPROVED AND SHATTER PROOF. WE'RE NOT GONNA PUT THE CONVERTER IN YET. WE'RE STILL IN MOCK UP STAGE. BEFORE OUR POWERHOUSE GOES IN, WE ARE UPGRADING THE CLAM SHELL BUSHINGS WITH URETHANE ONES FROM PROTHANE. NOW THE HOLLEY LS SWAP BRACKETS CAN

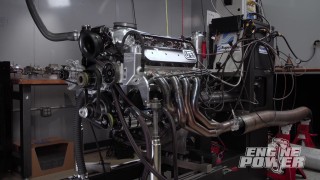

BOLT TO THE ENGINE. OKAY WE'RE GONNA START RUNNING INTO SOMETHING ON THE STOP RIGHT THERE. IT'S TIME TO START A RELATIONSHIP LIKE YOU'D SEE AT A BAR. OLD GRAY HAIR IS HOOKING UP WITH YOUNG, LEAN, AND MEAN LS POWER.

(MIKE)>> LET THE JACK DOWN JUST A HAIR. WE HOME FREE BABY.

(PAT)>> WITH THE THROUGH BOLTS TIGHT, WE'RE TAKING A BREAK.

(MIKE)>> WE'RE BACK AND SUPER PLEASED AT HOW THE LSA FITS IN THIS CAPRICE. NOW BY THE IRROMETER, IT LOOKS LIKE WE HAVE PLENTY OF ROOM FOR THE HEADERS AND THE REST OF THE COMPONENTS TO FINISH OFF THE ENGINE BAY, BUT FOR RIGHT NOW WE HAVE JUST ENOUGH TIME TO MOUNT UP THE TRANSMISSION AND GET AN IDEA OF HOW WE'RE GONNA BUILD THE CROSSMEMBER. WITH THE TRANS ON OUR MATCO TRANS JACK WE CAN RAISE IT UP. LIKE PAT MENTIONED, THIS IS JUST MOCK UP. SO THE CONVERTER ISN'T IN. WE'LL ALIGN THE BELL HOUSING WITH THE BLOCK'S

DOWELS AND START A FEW ARP FASTENERS. WE'RE GONNA HAVE TO BUILD A TUBULAR CROSSMEMBER

FOR THIS ENGINE AND TRANSMISSION SETUP. THE FACTORY ONE JUST WON'T CUT IT, BUT THAT'S GONNA HAPPEN NEXT TIME ALONG WITH SOME COOL

ELECTRONICS, THE EXHAUST, FUEL SYSTEM, AND A BUNCH OF OTHER TRICK PARTS. NOW WE'RE WELL ON OUR WAY TO HAVING ONE OF THE

BADDEST CAPRICES YOU'VE SEEN IN QUITE A WHILE, DON'T MISS IT.

(PAT)>> HOOKER IS ARGUABLE THE MOST RECOGNIZED NAME IN HEADERS, AND THESE ARE FROM THEIR NEW BLACKHEART LINE AND FIT A 2015 MUSTANG WITH A

FIVE LITER ENGINE. THEY FEATURE ONE AND SEVENEIGHTHS DIAMETER LONG TUBE PRIMARIES MADE FROM LIGHTWEIGHT 18 GAUGE T-304 STAINLESS FOR DURABILITY. THEY ALSO HAVE THREEEIGHTHS THICK LASER

CUT FLANGES FOR A LEAK PROOF SEAL, AND EVEN HAVE

A TRICK MERGE COLLECTOR BORROWED FROM THE RACING WORLD TO OPTIMIZE FLOW. THEY'RE A HIGH TUCK FIT AND ARE DESIGNED TO GO IN WITHOUT DROPPING YOUR KMEMBER, WHICH GREATLY SIMPLIFIES YOUR INSTALLATION. THEY COME WITH MOUNTING HARDWARE AND OTWO EXTENSIONS TO DO THE JOB RIGHT ALL FOR UNDER $900 BUCKS. AND YOU CAN SEE THE ENTIRE LINE OF THE BLACKHEART PERFORMANCE EXHAUST FOR YOUR LATE MODEL MUSCLE AT HOLLEY DOT COM. SINCE ITS CREATION IN 1953, WD 40 HAS PROVEN

ITSELF TO BE ONE OF THE MOST VERSATILE PRODUCTS THAT YOU CAN HAVE IN YOUR HOUSE, GARAGE, OR TOOL BOX. AND EVEN THOUGH THE ORIGINAL FORMULATION HAS REMAINED UNCHANGED, THE SAME CAN'T BE SAID ABOUT ITS DELIVERY SYSTEM.

THE EASY REACH FLEXIBLE STRAW IS THE LATEST HIGH TECH VERSION THAT'S ABLE TO BEND AND KEEP IT SHAPED TO HIT PREVIOUSLY UNREACHABLE SPOTS YOU ARE WORKING ON NO MATTER WHERE THEY ARE. AND FOR AN ADDED BONUS IT'LL ALSO SPRAY THE CONVENTIONAL WAY WITH THE STRAW FLIPPED DOWN. PICK UP A CAN OR TWO AT YOUR LOCAL PARTS STORE FOR AROUND EIGHT BUCKS.

(MIKE)>> TODAY'S TECH TIP IS ALL ABOUT FUEL DELIVERY.

NOW IT DOESN'T MATTER IF YOU'RE WORKING WITH A CARBURETOR OR FUEL INJECTION, THERE'S A SCIENCE TO DESIGNING A SYSTEM TO MEET THE ENGINE REQUIREMENTS FOR FUEL SUPPLY. NOW IN THE PAST WE SHOWED YOU HOW TO PICK A CARBURETOR OUT FOR YOUR ENGINE BASED OFF A SIMPLE FORMULA. TODAY WE'RE GOING TO SHOW YOU A COUPLE OF EXAMPLES OF HOW TO GET THE FUEL TO THE DELIVERY SYSTEM WHETHER YOU'RE WORKING WITH AN OLD SCHOOL CARBURETOR OR NEW AGE FUEL INJECTION.

(PAT)>> THERE ARE SEVERAL DIFFERENT TYPES OF FUEL PUMPS ON THE MARKET. LOW PRESSURE APPLICATIONS FOR CARB COME IN A COUPLE OF DIFFERENT FORMS. THESE ARE MECHANICAL THAT BOLT TO THE ENGINE AND ARE DRIVEN BY THE CAM LOBE AND A ROD THAT ACTUATES THIS ARM. THEY CAN DELIVER BETWEEN THREE AND SEVEN PSI, WHICH IS ALL THAT'S NEEDED, AND IN RARE CASES THERE ARE SOME MECHANICAL PUMPS THAT CAN SUPPLY EFI PRESSURE LEVELS.

(MIKE)>> ELECTRIC PUMPS CAN BE INTERNALLY OR EXTERNALLY REGULATED. THEY COME IN A MYRIAD OF SIZES FROM ONES THAT DUPLICATE MECHANICAL PUMP CAPABILITY TO HIGH FLOW, HIGH PRESSURE MONSTERS THAT CAN SUPPLY ENOUGH FUEL TO SUPPORT ENGINES IN EXCESS OF

3,500 HORSEPOWER.

(PAT)>> IN TANK PUMPS LIKE THIS ARE ELECTRIC AND

MOUNT INSIDE A FUEL TANK OR A CELL. THEY ARE USUALLY RATED IN LITERS PER HOUR, AND IF YOU WANT TO UPGRADE YOUR FUEL SYSTEM AND KEEP THE STOCK APPEARANCE THIS IS THE WAY TO GO. IN LINE PUMPS MOUNT TO FRAME RAILS OR TO THE

UNDERSIDE OF A VEHICLE. IN OUR OPINION THESE ARE THE MOST UNIVERSAL AND ARE AVAILABLE IN SIZES THAT WILL SUPPORT ANY

HORSEPOWER RATING. SOME ARE INTERNALLY REGULATED, BUT MOST AFTERMARKET ONES REQUIRE THE USE OF THIS.

(MIKE)>> AN EXTERNAL FUEL PRESSURE REGULATOR. NOW ITS JOB IS TO ACCURATELY REGULATE THE FUEL PRESSURE IN THE SYSTEM. NOW IT REGULATES THAT BY USING A DIAPHRAGM

AND SPRING INSIDE. NOW ONCE THAT LINE PRESSURE IS REACHED, ANY EXCESS FUEL IS SENT TO THE RETURN SIDE OF THE REGULATOR AND FORCE BACKED TO THE TANK. HERE'S AN EXAMPLE OF HOW WE RUN AN EFI FUEL SYSTEM. FROM THE TANK OR THE CELL WE RUN A SUPPLY LINE TO A 100 MICRON FUEL FILTER. NOW IT'S DESIGNED TO CATCH CONTAMINANTS THE SIZE OF BEACH SAND, COFFEE GROUNDS, AND TABLE SALT, AND IT WILL NOT PUT A STRAIN ON AN ELECTRIC PUMP, WHICH IS NEXT IN LINE. NOW MAKE SURE YOU MOUNT IT AS LOW AS POSSIBLE TO PROMOTE A GRAVITY FEED FROM THE TANK. AFTER THAT COMES A 10 MICRON FILTER. IT'S DESIGNED TO CATCH CONTAMINANTS MUCH SMALLER, LIKE DUST. WITHOUT IT DON'T BE SURPRISED IF YOU END UP WITH A CLOGGED FUEL INJECTOR. NOW FROM THAT FILTER WE RUN A LINE INTO THE BACK

SIDE OF ONE FUEL RAIL, CONNECT BOTH RAILS TOGETHER AT THE FRONT, AND THE BACK SIDE OF THIS RAIL BECOMES THE OUTLET TO THE REGULATOR. NOW THE REASON WE DO THAT IS WE WANT FULL PUMP

PRESSURE AT THE RAILS AT ALL TIMES. THIS PREVENTS AN UNWANTED PRESSURE DROP. NOW FROM THE REGULATOR WE RUN THE RETURN LINE ALL THE WAY BACK TO THE RETURN ON THE TANK, AND THAT COMPLETES THE SYSTEM.

(PAT)>> AND THAT COMPLETES OUR TECH TIP.

(MIKE)>> WELL THAT'S IT FOR PART ONE OF PART ONE OF GRAY HAIR WHITE KNUCKLE. NOW THE NEXT TIME YOU SEE IT YOU'RE GONNA GET TO HEAR WHAT 816 HORSEPOWER SOUNDS LIKE BETWEEN THE FRAME RAILS OF A '93 CAPRICE.

Show Full Transcript

IT'S ONE OF THE CLEANEST '93 CAPRICE CLASSICS WE HAVE SEEN IN A LONG TIME. THIS IS A FULL FRAME CAR WITH AN LOTHREE 305 BETWEEN ITS FENDERS. IT PRODUCES 170 HORSEPOWER AND A WIG SNATCHING 255 POUND FEET OF TORQUE. IT HAS AN IRON BLOCK AND CYLINDER HEADS, WHICH ARE TOPPED OFF WITH TBI INJECTION. THE INTERIOR HAS A DRIVE IN MOVIES BEST LAYOUT. A BIG FRONT BENCH SEAT, TILT WHEEL, AND PLENTY OF ROOM OUT BACK FOR 100 CHIHUAHUAS SPORTING THEIR LITTLE BOWS. THIS CAR'S PURPOSE FROM DAY ONE WAS TO BE A

CRUISER FOR LET'S JUST SAY SENIOR CITIZENS. WITH ITS FOURL-60 AUTOMATIC TRANSMISSION AND 2.56 REAR GEAR IT WAS ALL ABOUT FUEL ECONOMY AND COMFORTABLY BLOCKING THE FAST LANE ON THE INTERSTATE. HERE'S WHERE THAT OFF THE WALL BUILD COMMENT COMES INTO PLAY. REMEMBER THIS LSA? IT'S THE ONE PAT AND I BUILT WITH A COUPLE OF GUYS FROM THE SCHOOL OF AUTOMOTIVE MACHINISTS. NOW IT PACKS 427 CUBIC INCHES AND RUNS ON 93 OCTANE PUMP GAS. NOW IT MAKES 816 HORSEPOWER, WHICH IS OVER FOUR TIMES THE AMOUNT OF THAT 305 THAT'S IN THE CAPRICE NOW. NOW AS FAR AS TORQUE, THIS THING MAKES ALMOST AS MUCH AS A NEW CUMMINS TURBO DIESEL WITH 797 POUND FEET OF TORQUE.

(PAT)>> THAT ENGINE NEEDS TO BE BACKED WITH COMPONENTS THAT WILL HANDLE THE ROWDINESS WHEN THE LOUD PEDAL HITS THE FLOOR, AND IT STARTS WITH THIS SIX SPEED AUTOMATIC TRANSMISSION THAT'S RATED

TO HANDLE 850 HORSEPOWER. YUKON GEAR AND AXLE SUPPLIED A FULL TILT REBUILD FOR THE REAR END, WHICH WE SOURCED FROM A DIFFERENT CAPRICE. AND THE REAR SUSPENSION IS SIMPLE YET EFFECTIVE WITH A BUNCH OF QUALITY AFTERMARKET COMPONENTS FROM SUMMIT RACING, BUT BEFORE WE CAN PUT ALL THESE COOL PARTS IN THERE'S A LOT OF WORK THAT'S GOT TO BE DONE AND IT STARTS WITH THE TEAR DOWN.

WE'RE STARTING AT THE TOP WITH THE UPPER FAN SHROUD,

FAN, AND AIR BOX. OH TROUBLE! THERE'S A LOT OF SMALL STUFF THAT NEEDS TO BE DISCONNECTED AND IT'S PACKED IN HERE. A LOT OF IT IS NOT NEEDED BUT IT'S STILL NICE TO SALVAGE ALL WE CAN. TO THE BOTTOM WE GO. YOU'VE SEEN US PULL ENGINES AND TRANS FROM LATE MODEL CARS AND THEY CAME OUT THE BOTTOM. NOT THIS FULL FRAME CRUISER. WE'LL REMOVE THE TRANS FROM DOWN HERE. ALRIGHT ONE TRANSMICHIGAN REMOVED! AND THEN GO BACK UP TOP TO REMOVE THE ENGINE. AS FAR AS WE KNOW EVERYTHING IS DISCONNECTED. SO OUR MATCO ENGINE LIFT CAN GET TO WORK.

WITH A LITTLE LIFT, A LITTLE SHAKE, THIS 305 IS COMING OUT AND NEVER RETURNING. AND WE ARE CLEAR! I WONDER HOW MANY TIMES THIS GOT DRIVEN TO BINGO?

NOW A LITTLE CLEAN UP JOB WITH THE PRESSURE WASHER. ALL IT'S DOING IS KNOCKING OUT SOME DIRT. I DON'T THINK THIS CAR EVER HAD A FLUID LEAK. WITH IT CLEAN ENOUGH WE'RE CHANGING OUR ATTENTION TO THE REAR END.

THIS IS A SEVEN POINT FIVE INCH REAR, AND IT WON'T HOLD UP TO OUR LSA'S POWER. SO IT'S GOT TO GO. PULLING IT IS SIMPLE. UNBOLT THE SHOCKS, REMOVE THE COIL SPRINGS, UNDO THE FOUR FASTENERS HOLDING THE UPPER AND LOWER CONTROL ARMS TO THE FRAME. NOW SUPPORT IT, PULL THE BOLTS, AND RAISE THE CAR AWAY FROM IT. DON'T WORRY, WE DIDN'T FORGET THE BRAKE ABS LINES. KNOWING THAT THIS STOCK SEVEN POINT FIVE INCH AXLE WOULDN'T LAST LONG FOR WHAT WE'RE DOING WITH THIS BUILD, WE SOURCED A TAKE OUT EIGHT POINT FIVE INCH

10 BOLT REAR END. THE EIGHT POINT FIVE REFERS TO THE DIAMETER OF THE RING GEAR, AND THAT REQUIRES A PHYSICALLY LARGER HOUSING THAT IS MORE CAPABLE OF HANDLING THE ADDITIONAL POWER. THIS AXLE IS A DIRECT BOLT IN FOR OUR CAPRICE WITH ALL OF THE SUSPENSION BRACKETS, BRAKE LINE MOUNTS, AND EVEN THE ABS SENSOR ALL IN THE SAME SPOT. BUT BEFORE WE DO THAT WE'RE GONNA REBUILD AND UPGRADE ALL THE INTERNALS. WE ONLY HAVE TO USE THE HOUSING ITSELF. SO EVERYTHING GETS REMOVED TO GET CLEANED UP FOR NEW PARTS. FIRST I'LL POP THE REAR COVER TO TAKE A LOOK AND SEE THAT THE FLUID IS ALREADY DRAINED. NEXT ALL THE OLD BRAKE STUFF CAN COME OFF AS WELL. AN IMPALA SS HAS REAR DISCS. THIS HOUSING IS FROM A HEAVY DUTY CAPRICE, LIKE A TAXI, AND IS SETUP WITH DRUM BRAKES. THESE ARE A "C" CLIP STYLE AXLE, SO THE PIN CAN BE TAKEN OUT, THE AXLES PUSHED INWARD, AND THE "C" CLIPS CAN BE REMOVED. THAT ALLOWS THE AXLES TO SLIDE RIGHT OUT. HERE'S A LITTLE TIP. USE A STAMP OR A CHISEL TO MARK THE ORIENTATION OF THE DIFFERENTIAL CAPS. NOW LOOSEN AND REMOVE THE CAPS AND THE DIFF AND RING GEAR IS READY TO COME OUT. BE SURE TO KEEP TRACK OF THE SHIM POSITIONS VERY CAREFULLY. THIS WILL HELP GET THINGS SETUP QUICKER ON REASSEMBLY.

THE PINION NUT IS REMOVED AT THIS TIME AND THE PINION COMES RIGHT OUT. FINALLY I'LL CLEAN OUT THE WHOLE THING WITH DEGREASER, SCOTT SHOP TOWELS, AND SOME ELBOW GREASE. WE'LL GET TO THE REBUILD AFTER THE BREAK.

(MIKE)>> WE'RE BACK, AND JUST LIKE PAT TOLD YOU, THE REBUILD STARTS NOW. YUKON GEAR AND AXLE IS OUR GO TO SOURCE FOR QUALITY AXLE COMPONENTS. NOW THEIR INVENTORY WILL ABSOLUTELY BLOW YOUR MIND. WHETHER YOU'VE GOT A PAVEMENT POUNDER OR A FULL BLOWN TRAIL RIG, THEY'VE GOT YOU COVERED. NOW WE'RE GONNA BUILD THAT EIGHT AND A HALF INCH 10 BOLT REAR END WITH THEIR GRIZZLY LOCKER AS THE CENTER PIECE. THIS ONE ACCEPTS 30 SPLINE AXLES AND COMES WITH AN OUTSTANDING WARRANTY. NOW DUE TO THE TORQUE CURVE OUR LSA PRODUCES WE'RE USING A 3.23 RING AND PINION SET, WHICH IS GONNA BE VERY MELLOW.

NOW THIS IS A TWO CUT DESIGN AND IT'S GUARANTEED TO RUN COOLER AND QUIETER THAN OTHER SETS ON THE MARKET. NOW AS FAR AS THE INSTALL KIT GOES IT SPEAKS FOR ITSELF. EVERYTHING YOU NEED TO GET THOSE COMPONENTS IN THE HOUSING. NOW WE'RE GONNA START BY GETTING THE PINION SETUP. A PRESS IS THE BEST THING TO USE FOR THIS. STAY AWAY FROM A HAMMER AND CHISEL. THIS SHIM IS FROM THE ORIGINAL PINION. IT'S ALWAYS A GOOD STARTING POINT SINCE IT CAME OUT OF THE SAME HOUSING. NOW THE BEARING IS PLACED OVER THE PINION GEAR, FOLLOWED BY A PIECE OF PIPE, AND A PIECE OF STEEL TO PRESS AGAINST. START APPLYING PRESSURE TO DRIVE THE BEARING ALL THE WAY TO THE SHIM. WHILE WE'RE HERE WE'LL ALSO PRESS THE

BEARINGS ON THE CARRIER. THERE ARE NO SHIMS USED HERE. THE PINION BEARING RACE IS READY TO GO IN THE HOUSING. ALWAYS USE A RACE INSTALLER LIKE THIS TO GET IT IN. LISTEN AS THE RACE IS TAPPED IN. YOU CAN HEAR AN AUDIBLE CHANGE WHEN IT IS SEATED.

WITH THE HOUSING ROTATED 180 DEGREES WE CAN INSTALL THE OTHER RACE FOR THE PINION. IT GOES IN THE SAME WAY. NOW THE PINION GEAR CAN BE PLACED IN THE HOUSING, THE HOUSING ROTATED UP, AND PAT WILL DROP IN THE CRUSH SLEEVE AND BEARING, ALIGN THE YOKE WITH THE GEAR'S SPLINES, AND USE THE NUT TO RUN IT DOWN. GETTING THE CRUSH SLEEVE TO ACTUALLY

CRUSH CAN BE A CHORE. JUST KEEP AT IT. WITH THE SLACK OUT, I'LL USE A BEAM TYPE TORQUE WRENCH TO CHECK THE BEARING'S PRELOAD. 16 TO 19 INCH POUNDS IS THE TARGET. IT'S NOT ENOUGH YET. A LITTLE MORE WANG DANG WITH THE IMPACT AND ANOTHER CHECK. 15, 16, IT'S PERFECT! THIS IS ALL SETUP WORK AND NOT FINAL ASSEMBLY. THE RING GEAR IS NEXT.

NEVER USE THE BOLTS TO PULL IT ON THE CARRIER. YOU'LL RISK STRIPPING THE THREADS OUT OF THE GEAR. I USUALLY PUT THESE IN AN OVEN SO THAT ITS JUST EVEN HEAT.

THE NEXT BEST THING IS A HEAT GUN. DON'T USE A TORCH. USING A TORCH WILL DESTROY THE HEAT TREAT OF THE GEAR.

(PAT)>> WHENEVER YOU'RE READY.

(MIKE)>> I'M READY. WITH OUR TARGET OF 200 DEGREES REACHED WE WILL PULL THE GEAR ONTO THE CARRIER. NOTICE HOW THE GEAR IS FULLY SEATED ALREADY. FINAL TORQUE WILL BE 60 POUND FEET.

(PAT)>> WITH THE PASSENGER SIDE SHIMS IN PLACE, THE GRIZZLY LOCKER GETS DROPPED IN. NOW THE DRIVER'S SIDE SHIMS CAN BE INSTALLED. THIS IS A SNUG FIT TO ENSURE THE BEARINGS ARE SLIGHTLY PRELOADED. USING A BRASS DRIVE, SEAT THE SHIMS. NOW THE ORIGINAL CAPS CAN GO ON IN THEIR MARKED LOCATIONS, AND TORQUED TO 65 POUND FEET. THE GEAR NOISE YOU HEARD IS CALLED BACKLASH. THE SPEC FOR IT SHOULD BE BETWEEN THREE AND SIX THOUSANDTHS. A DIAL INDICATOR ALLOWS US TO MEASURE THE BACKLASH ACCORDINGLY. THE GAUGE IS PLACED ON A SINGLE TOOTH OF THE RING GEAR. NOW ZERO IT OUT.

THE GAUGE SHOWS WE HAVE SIX THOUSANDTHS, SO WE ARE IN THE CORRECT RANGE. HERE'S A CLOSE UP OF WHAT SIX THOUSANDTHS OF BACKLASH LOOKS LIKE. GEAR MARKING COMPOUND IS USED TO CHECK THE PATTERN, OR GEAR MESH, BETWEEN THE RING AND PINION. NOW TURN THE PINION AND HOLD A HAND ON THE DIFF FOR SOME RESISTANCE. THIS WILL ALLOW THE MARK TO BE VERY VISIBLE ON THE DRIVE SIDE. IT SHOWS WE HAVE AN ACCEPTABLE PATTERN PER THE YUKON INSTRUCTION GUIDE.

WITH THE SETUP COMPLETE IT ALL COMES BACK OUT. SO THE NEW PINION BEARING AND ABS RELUCTOR CAN GO ON. WITH THE PINION BEARING PRELOAD BACK AT 16 INCH POUNDS WITH THE NEW CRUSH SLEEVE, THE DIFF DROPS IN FOR GOOD USING THE SAME SHIM PACKS, AND THE CAPS

GET TORQUED TO 65 POUND FEET. THE GEAR AND DIFF INSTALL IS NOW COMPLETE.

(MIKE)>> THE AXLE BEARINGS CAN GO IN NOW. A FEW TAPS WITH THE HAMMER AND THEY'RE INSTALLED. WE ALWAYS USE A LITTLE SILICONE AROUND THE OUTER SHELL OF THE AXLE SEALS. IT'S AN EASY WAY TO PREVENT A LEAK. WITH A FEW TAPS THEY'RE IN AS WELL. YUKON AXLES ARE A ONE PIECE FORGED 1541-H MATERIAL. THEY ARE 25 PERCENT STRONGER THAN OE AXLES,

WHICH IS A LOT. THE CENTER PIN IS REMOVED FROM THE DIFF, WHICH ALLOWS THE AXLES TO SLIDE IN FAR ENOUGH TO

INSTALL THE "C" CLIPS. USING A MAGNET, POSITION THE CLIP OVER THE GROOVE IN THE AXLE AND PULL IT OUTWARD. THE SAME GOES FOR THE OTHER SIDE. NOW THE PIN IS REINSTALLED AND THE AXLES ARE CAPTURED. YUKON ALSO SENT US THIS DIFFER COVER GASKET, AND A TA PERFORMANCE REAR GIRDLE. IT'S CAST ALUMINUM. ONCE THE COVER IS BOLTED TO THE HOUSING AND TORQUED TO 25 POUND FEET, SCREW THE LOAD BOLT IN BY HAND UNTIL IT MAKES CONTACT WITH THE BEARING CAP, AND TORQUE IT TO FIVE POUND FEET. THE JAM NUT IS RAN DOWN AND TORQUED TO 20 POUND FEET. THIS GIRDLE APPLIES SLIGHT PRESSURE TO THE BEARING CAPS OF THE DIFF, PREVENTING THE CAPS FROM PUSHING BACKWARDS DURING HARD ACCELERATION, CAUSING A FAILURE.

THE FINAL PIECE BEFORE IT GOES IN IS THE ABS SENSOR. WHEN WE COME BACK IT'S GETTING MATED TO THE CAPRICE.

(MIKE)>> WE'RE BACK AND IT'S TIME TO HANG THE REAR END. NOW IT'S NOT GOING BACK IN ITS ORIGINAL LOCATION. WE ORDERED THESE UPPER AND LOWER CONTROL ARMS FROM SUMMIT RACING AND THEY'RE DESIGNED TO POSITION THE REAR AXLE BACK IN THE CENTER OF THE WHEEL WELL. NOW IN CASE YOU DIDN'T NOTICE THE ORIGINAL LOCATION, HERE'S A QUICK LOOK.

(PAT)>> THEY'RE FILLED WITH URETHANE BUSHINGS

AND ZIRK FITTINGS. THE UPPER CONTROL ARMS ARE FULLY ADJUSTABLE FRONT AND REAR, WHICH ALLOWS US TO SET THE PINION ANGLE WHEREVER WE WANT IT. NOW THE FIRST THING TO DO IS PREP THEM. ALWAYS APPLY CHASSIS GREASE TO THE OUTSIDE OF THE BUSHINGS. THIS PREVENTS ANNOYING SQUEAKS AND PREMATURE WEAR AGAINST THE FRAME'S BRACKETS. ANOTHER SMART THING TO DO IS APPLY A GENEROUS AMOUNT OF ANTISEIZE TO THE BOLTS THAT SECURE THEM. THIS PREVENTS THE BOLT FROM CORRODING AGAINST THE INNER SLEEVE OF THE BUSHING OVER TIME, ESPECIALLY IF YOU'RE UP NORTH.

(PAT)>> FOR THIS CAR'S PURPOSE WE NEED A SHOCK

THAT WILL DO IT ALL, MEANING WE WANT TO AUTOCROSS IT, TAKE IT DOWN THE DRAG STRIP, AND HAVE EXCELLENT RIDE QUALITY ON THE STREET. QA ONE, WHO IS A LEADER IN SUSPENSION COMPONENTS, CAME TO THE RESCUE WITH THESE DOUBLE ADJUSTABLES THAT WERE DESIGNED FOR GM "B" BODIES. ONE KNOB IS FRO REBOUND, THE OTHER FOR COMPRESSION. SO WE GET INDEPENDENT ADJUSTMENT FOR BOTH DIRECTIONS OF SHOCK TRAVEL.

(MIKE)>> NOW THE CAR IS LOWERED TO THE REAR END AND THE CONNECTIONS ARE MADE. THE NEW LOWERING SPRINGS, WHICH ARE MUCH SHORTER

THAN STOCK, CAN GO IN NOW, AND THE SHOCKS ATTACH TO THE HOUSING.

(PAT)>> NOW THAT THE WEIGHT IS OUT BACK, WE'RE GONNA GET THE ENGINE AND TRANSMISSION READY TO GO IN. FIVE YEARS AGO WE BUILT A '97 THUNDERBIRD DUBBED "DEEP SLEEP". IT HAD A SIX SPEED AUTO BEHIND A 600 HORSEPOWER

SMALL BLOCK FORD. WELL WE KEPT THE TRANS AROUND AND IT'S GOING IN GRAY HAIR, WHITE KNUCKLE. IN ORDER TO DO SO THIS BELL HOUSING WITH THE FORD PATTERN MUST GO, AND A GM PATTERN GOES IN ITS PLACE.

IT'S MADE BY REED AND IS SFI APPROVED AND SHATTER PROOF. WE'RE NOT GONNA PUT THE CONVERTER IN YET. WE'RE STILL IN MOCK UP STAGE. BEFORE OUR POWERHOUSE GOES IN, WE ARE UPGRADING THE CLAM SHELL BUSHINGS WITH URETHANE ONES FROM PROTHANE. NOW THE HOLLEY LS SWAP BRACKETS CAN

BOLT TO THE ENGINE. OKAY WE'RE GONNA START RUNNING INTO SOMETHING ON THE STOP RIGHT THERE. IT'S TIME TO START A RELATIONSHIP LIKE YOU'D SEE AT A BAR. OLD GRAY HAIR IS HOOKING UP WITH YOUNG, LEAN, AND MEAN LS POWER.

(MIKE)>> LET THE JACK DOWN JUST A HAIR. WE HOME FREE BABY.

(PAT)>> WITH THE THROUGH BOLTS TIGHT, WE'RE TAKING A BREAK.

(MIKE)>> WE'RE BACK AND SUPER PLEASED AT HOW THE LSA FITS IN THIS CAPRICE. NOW BY THE IRROMETER, IT LOOKS LIKE WE HAVE PLENTY OF ROOM FOR THE HEADERS AND THE REST OF THE COMPONENTS TO FINISH OFF THE ENGINE BAY, BUT FOR RIGHT NOW WE HAVE JUST ENOUGH TIME TO MOUNT UP THE TRANSMISSION AND GET AN IDEA OF HOW WE'RE GONNA BUILD THE CROSSMEMBER. WITH THE TRANS ON OUR MATCO TRANS JACK WE CAN RAISE IT UP. LIKE PAT MENTIONED, THIS IS JUST MOCK UP. SO THE CONVERTER ISN'T IN. WE'LL ALIGN THE BELL HOUSING WITH THE BLOCK'S

DOWELS AND START A FEW ARP FASTENERS. WE'RE GONNA HAVE TO BUILD A TUBULAR CROSSMEMBER

FOR THIS ENGINE AND TRANSMISSION SETUP. THE FACTORY ONE JUST WON'T CUT IT, BUT THAT'S GONNA HAPPEN NEXT TIME ALONG WITH SOME COOL

ELECTRONICS, THE EXHAUST, FUEL SYSTEM, AND A BUNCH OF OTHER TRICK PARTS. NOW WE'RE WELL ON OUR WAY TO HAVING ONE OF THE

BADDEST CAPRICES YOU'VE SEEN IN QUITE A WHILE, DON'T MISS IT.

(PAT)>> HOOKER IS ARGUABLE THE MOST RECOGNIZED NAME IN HEADERS, AND THESE ARE FROM THEIR NEW BLACKHEART LINE AND FIT A 2015 MUSTANG WITH A

FIVE LITER ENGINE. THEY FEATURE ONE AND SEVENEIGHTHS DIAMETER LONG TUBE PRIMARIES MADE FROM LIGHTWEIGHT 18 GAUGE T-304 STAINLESS FOR DURABILITY. THEY ALSO HAVE THREEEIGHTHS THICK LASER

CUT FLANGES FOR A LEAK PROOF SEAL, AND EVEN HAVE

A TRICK MERGE COLLECTOR BORROWED FROM THE RACING WORLD TO OPTIMIZE FLOW. THEY'RE A HIGH TUCK FIT AND ARE DESIGNED TO GO IN WITHOUT DROPPING YOUR KMEMBER, WHICH GREATLY SIMPLIFIES YOUR INSTALLATION. THEY COME WITH MOUNTING HARDWARE AND OTWO EXTENSIONS TO DO THE JOB RIGHT ALL FOR UNDER $900 BUCKS. AND YOU CAN SEE THE ENTIRE LINE OF THE BLACKHEART PERFORMANCE EXHAUST FOR YOUR LATE MODEL MUSCLE AT HOLLEY DOT COM. SINCE ITS CREATION IN 1953, WD 40 HAS PROVEN

ITSELF TO BE ONE OF THE MOST VERSATILE PRODUCTS THAT YOU CAN HAVE IN YOUR HOUSE, GARAGE, OR TOOL BOX. AND EVEN THOUGH THE ORIGINAL FORMULATION HAS REMAINED UNCHANGED, THE SAME CAN'T BE SAID ABOUT ITS DELIVERY SYSTEM.

THE EASY REACH FLEXIBLE STRAW IS THE LATEST HIGH TECH VERSION THAT'S ABLE TO BEND AND KEEP IT SHAPED TO HIT PREVIOUSLY UNREACHABLE SPOTS YOU ARE WORKING ON NO MATTER WHERE THEY ARE. AND FOR AN ADDED BONUS IT'LL ALSO SPRAY THE CONVENTIONAL WAY WITH THE STRAW FLIPPED DOWN. PICK UP A CAN OR TWO AT YOUR LOCAL PARTS STORE FOR AROUND EIGHT BUCKS.

(MIKE)>> TODAY'S TECH TIP IS ALL ABOUT FUEL DELIVERY.

NOW IT DOESN'T MATTER IF YOU'RE WORKING WITH A CARBURETOR OR FUEL INJECTION, THERE'S A SCIENCE TO DESIGNING A SYSTEM TO MEET THE ENGINE REQUIREMENTS FOR FUEL SUPPLY. NOW IN THE PAST WE SHOWED YOU HOW TO PICK A CARBURETOR OUT FOR YOUR ENGINE BASED OFF A SIMPLE FORMULA. TODAY WE'RE GOING TO SHOW YOU A COUPLE OF EXAMPLES OF HOW TO GET THE FUEL TO THE DELIVERY SYSTEM WHETHER YOU'RE WORKING WITH AN OLD SCHOOL CARBURETOR OR NEW AGE FUEL INJECTION.

(PAT)>> THERE ARE SEVERAL DIFFERENT TYPES OF FUEL PUMPS ON THE MARKET. LOW PRESSURE APPLICATIONS FOR CARB COME IN A COUPLE OF DIFFERENT FORMS. THESE ARE MECHANICAL THAT BOLT TO THE ENGINE AND ARE DRIVEN BY THE CAM LOBE AND A ROD THAT ACTUATES THIS ARM. THEY CAN DELIVER BETWEEN THREE AND SEVEN PSI, WHICH IS ALL THAT'S NEEDED, AND IN RARE CASES THERE ARE SOME MECHANICAL PUMPS THAT CAN SUPPLY EFI PRESSURE LEVELS.

(MIKE)>> ELECTRIC PUMPS CAN BE INTERNALLY OR EXTERNALLY REGULATED. THEY COME IN A MYRIAD OF SIZES FROM ONES THAT DUPLICATE MECHANICAL PUMP CAPABILITY TO HIGH FLOW, HIGH PRESSURE MONSTERS THAT CAN SUPPLY ENOUGH FUEL TO SUPPORT ENGINES IN EXCESS OF

3,500 HORSEPOWER.

(PAT)>> IN TANK PUMPS LIKE THIS ARE ELECTRIC AND

MOUNT INSIDE A FUEL TANK OR A CELL. THEY ARE USUALLY RATED IN LITERS PER HOUR, AND IF YOU WANT TO UPGRADE YOUR FUEL SYSTEM AND KEEP THE STOCK APPEARANCE THIS IS THE WAY TO GO. IN LINE PUMPS MOUNT TO FRAME RAILS OR TO THE

UNDERSIDE OF A VEHICLE. IN OUR OPINION THESE ARE THE MOST UNIVERSAL AND ARE AVAILABLE IN SIZES THAT WILL SUPPORT ANY

HORSEPOWER RATING. SOME ARE INTERNALLY REGULATED, BUT MOST AFTERMARKET ONES REQUIRE THE USE OF THIS.

(MIKE)>> AN EXTERNAL FUEL PRESSURE REGULATOR. NOW ITS JOB IS TO ACCURATELY REGULATE THE FUEL PRESSURE IN THE SYSTEM. NOW IT REGULATES THAT BY USING A DIAPHRAGM

AND SPRING INSIDE. NOW ONCE THAT LINE PRESSURE IS REACHED, ANY EXCESS FUEL IS SENT TO THE RETURN SIDE OF THE REGULATOR AND FORCE BACKED TO THE TANK. HERE'S AN EXAMPLE OF HOW WE RUN AN EFI FUEL SYSTEM. FROM THE TANK OR THE CELL WE RUN A SUPPLY LINE TO A 100 MICRON FUEL FILTER. NOW IT'S DESIGNED TO CATCH CONTAMINANTS THE SIZE OF BEACH SAND, COFFEE GROUNDS, AND TABLE SALT, AND IT WILL NOT PUT A STRAIN ON AN ELECTRIC PUMP, WHICH IS NEXT IN LINE. NOW MAKE SURE YOU MOUNT IT AS LOW AS POSSIBLE TO PROMOTE A GRAVITY FEED FROM THE TANK. AFTER THAT COMES A 10 MICRON FILTER. IT'S DESIGNED TO CATCH CONTAMINANTS MUCH SMALLER, LIKE DUST. WITHOUT IT DON'T BE SURPRISED IF YOU END UP WITH A CLOGGED FUEL INJECTOR. NOW FROM THAT FILTER WE RUN A LINE INTO THE BACK

SIDE OF ONE FUEL RAIL, CONNECT BOTH RAILS TOGETHER AT THE FRONT, AND THE BACK SIDE OF THIS RAIL BECOMES THE OUTLET TO THE REGULATOR. NOW THE REASON WE DO THAT IS WE WANT FULL PUMP

PRESSURE AT THE RAILS AT ALL TIMES. THIS PREVENTS AN UNWANTED PRESSURE DROP. NOW FROM THE REGULATOR WE RUN THE RETURN LINE ALL THE WAY BACK TO THE RETURN ON THE TANK, AND THAT COMPLETES THE SYSTEM.

(PAT)>> AND THAT COMPLETES OUR TECH TIP.

(MIKE)>> WELL THAT'S IT FOR PART ONE OF PART ONE OF GRAY HAIR WHITE KNUCKLE. NOW THE NEXT TIME YOU SEE IT YOU'RE GONNA GET TO HEAR WHAT 816 HORSEPOWER SOUNDS LIKE BETWEEN THE FRAME RAILS OF A '93 CAPRICE.