Engine Power Featured Projects

Engine Power Builds

Want more content like this?

Join the PowerNation Email NewsletterParts Used In This Episode

ARP

ARP Fasteners

ARP

Rocker Arm Studs

Callies

Compstar Connecting Rods

Callies

Compstar Crankshaft

Comp Cams

Conical Valve Springs

Comp Cams

Endure-X Solid Roller Lifters

Comp Cams

Keyway Adjustable Billet Timing Set

Comp Cams

Ultra Pro Magnum XD Roller Rocker Arms

CWT Industries

Multi-Bal 5500

DSS Racing

Piston Rings

DSS Racing

Small Block Chevy FXK2 Series Piston Set

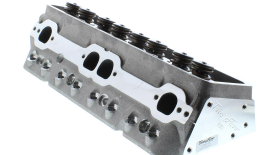

Edelbrock

Victor E 23 Degree Intake Manifold

Fluidampr

Harmonic Balancer

Holley

MSD Pro-Billet Distributor

Holley

Quick Fuel Q-Series Carburetor 950CFM

Lubrication Specialties

Hot Shot's Secret Adrenaline Assembly Lubricant

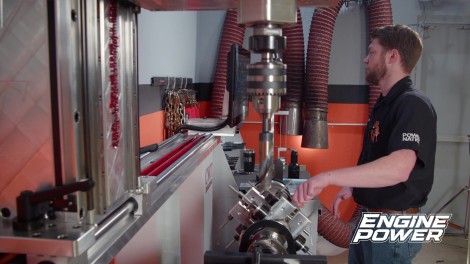

MSC

Vectrax Milling Machine