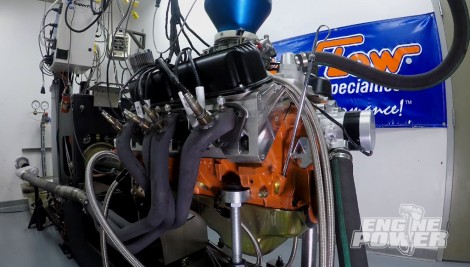

Assembling a 410 Mopar with High Flow Induction

Mopar fans rejoice! Chrysler’s venerable muscle car powerplant gets a big cubic inch increase and the induction package you’ve been asking for.

Season 7

Episode 9