Expert Engine Builders Answer Your Top 10 Questions Sent By Viewers

As much as Pat and Frankie love building engines on Engine Power, we receive lots of questions from viewers. Sometimes it’s advice for certain projects. Other times it is about what’s lurking in Pat’s shirt pocket. So we reached out on our social media for your most intriguing questions, and Pat and Frankie are going to answer them! We received hundreds of submissions, so we whittled down to ten. So let’s get started!

1. Daily Driving a Solid Roller Camshaft

Q: “Can a solid roller camshaft and valve train work for a street car used for everyday driving?”

Frankie: The short answer is “yes.”

Pat: The long answer is “yes”, but there’s more to it.

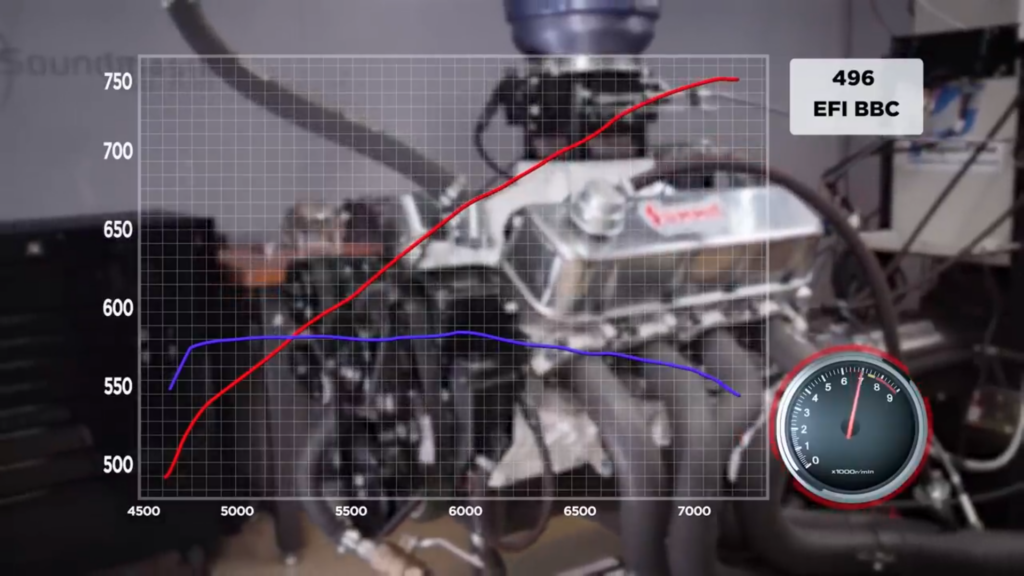

Frankie: We actually covered this in season 10 episode 3 of the show with our 496 big block Chevy. We went over the pros and cons of a solid roller street setup, and in our mind, it’s mostly pros. There are a few more maintenance items you have to do, like check the lash every now and then, and it’s a good idea to raise the idle RPM of the engine since a low idle RPM can potentially kill solid roller lifters.

Pat: Plus, we proved this on the street with our Granada, full street car, big solid roller turns, a lot of RPM. But we drive it around like a grandma car, and we go to the strip and pound on it so we know that it works.

2. Our First Engines

Q: “What was the first engine you ever worked on?”

Pat: The first engine I ever worked on was, it was a five-horse Briggs and Strat, and when I was about six or seven. That’s what really sparked mechanical knowledge and that quest for it.

Frankie: Yeah, mine was a 3406b CAT engine. A big inline six, like an industrial engine you would find like in a truck or something. I took a diesel program in high school and that was the engine that we rebuilt as part of the final.

Pat: And you switched to gas thankfully, uh afterward?

Frankie: Yeah, performance is the name of the business. Heavy stuff’s not fun to work with, but still, I’ve done lots of that as well.

3. Ring Gaps for Your Engine

Q: “Can you clarify what ring gaps you would use on different types of engines such as boosted nitrous or Na, and do clearances or torque specs on rod main bearings change for any of that? Also what rules of thumb do you stick to regarding rod and main bearing clearances?”

Pat: You want to take the first one?”

Frankie: Yeah. So ring manufacturers usually have specifications for what their ring gap should be based on the cylinder pressure and horsepower that you’re going to be running. It depends on material, heat, power adders, all kinds of stuff. So the safe bet is to follow the Piston Ring manufacturer’s specifications and remember a little bit bigger is always a little bit better

Pat: What about the torque stuff?

Frankie: Yeah, torque specs don’t really change. That’s based on the fastener itself, the strength, and the clamp load it needs. So those will not change based off of power level.

Pat: Now bearing clearance is something that everyone has questions on. Now you can always look in a manufacturer’s recommendation, whoever the bearing manufacturer is, because they’ll have stock specs on what that’s supposed to be. In performance applications, with most parts, you go a thousand per inch of shaft diameter. So if you have a 2-inch shaft you’ll use 2,000ds. But you’ll add half to that because the stock parts sometimes move around a little bit more depending on their material. So the better the material, the tighter you can run.

4. Pat’s Pocket Protector

Q: “Who actually uses everything in their pocket protector, and who just has it filled?”

Frankie: This is a big one.

Pat: I think we get this one a lot now. I use everything in it, and I actually have it on me, and this is what I carry in my pocket… in this actual case right here. So what’s in it? I have a mechanical pencil, a pen, and a marker. We all know what those are for. Reversible screwdriver. An automatic center punch. A scribe, an extending magnet, and a scale. I’ve been a machinist for 35 years, so I carry this with me since probably about 1985. So I use everything in it.

Frankie: I don’t keep mine on me because I’m not insane. But, I have pretty much the same stuff and we use them all the time it’s just handy to have it there because otherwise you have to look for it all the time that’s kind of annoying so I like having it right there.

Pat: I have a flashlight too.

Frankie: Yep, I have a flashlight. Leatherman as well. So yeah, love them. Use them all the time.

5. Solid Roller Lifters on a Hydraulic Roller Cam

Q: “What are your thoughts on running a solid roller lifter on a hydraulic roller cam?”

Pat: Yes that is 100% possible, but because the ramp intensities are different, you have to be a little bit careful. Doing it means you have to tight lash the actual lash on that lobe, plus your spring pressure is involved as well.

Frankie: Yeah, if you run too much lash, like say your solid roller lash is somewhere between 14 and 20, if you run that on a hydraulic roller, the ramp start is different and the roller actually runs into the ramp and does a lot of bad stuff and starts wrecking things. So usually if you tight lash them somewhere in the 5,000ths range it will work and it will run.

6. Working on Engine Power

Q: Pat, you’ve had a long, long, extremely long, really long career. What’s something you know now that you wish you knew when you first started your career?”

Pat: I guess it would be that a lot of things that I thought I had actual preconceived notions that were not true. So that it’s operating off of false data. There’s a lot of false data out there, and now with the internet up there, it’s even more so. There’s lots of good stuff as well, but I didn’t know that everything that wasn’t written in Granite, right? Everything’s like written on an ice cube because it’s going to change at some point. So that’s the thing that, if I wish I would have known that, I just can’t operate off of things that I think are verbatim.

Frankie: It also says here, “Frankie how did you become so attractive and good-looking?”

Pat: It does not say that!

Frankie: No it doesn’t it says:

Q: “Frankie, what’s the most surprising or unexpected thing about working on the show so far?”

Frankie: To be honest it’s a lot of fun. I thought it was going to be like, you know really hard work, and I thought TV was going to be really scary, and like there’s going to be a lot of lights and cameras and all this kind of stuff. But we have a lot of fun making the show. We have a lot of fun doing the projects that we get to do. So really it’s just it’s a dream job, and we really really enjoy it.

7. Plastigauge Colors

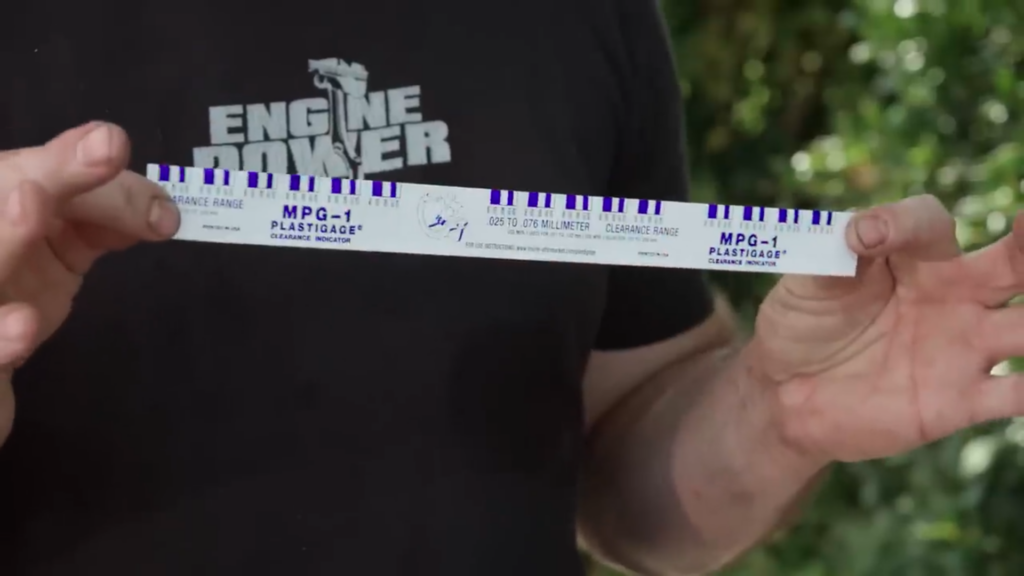

Q: “What are the different colors of plastigage for?”

Frankie: That’s a good question.

Pat: That’s a very good question. Now plastigage is a great tool to use if you don’t have a set of micrometers and a dial bore gauge. It’s very common to check your rod and main bearing clearances with it, and it comes in three different ranges: there’s green, there’s red, and there’s blue.

Frankie: Green is for ranges from .001ths to .003ths. Red is for ranges from .002ths to .006ths. And blue is for ranges from .004ths to .009ths of an inch. So depending on what you’re doing you’ll use a different color or the different thickness of plastigage for your application.

Pat: Now if you’re using blue on rod main bearings, you might want to check that out because that’s a little on the bank side.

Frankie: Or you’re working on a top fuel car.

Pat: Or… yeah.

8. Making the Show

Q: “How many hours a week does it take to stay on schedule with season production, builds, trips, Driveway Rescues, etc? Also, love the show. You two are both awesome and my favorite automotive show by far! I’ve been watching since the original shows were on TNN if that tells you anything.”

Frankie: That’s a long time, wow.

Pat: That’s that your mom who wrote that one.

Frankie: No, I don’t think my mom watches our show to be honest.

Pat: Her name’s different?

Frankie: Haha, no. Thank you for watching. We really appreciate it for sure, and as far as production goes, it takes quite a bit of time. We work a minimum of 10 hours a day, 5 days a week. Sometimes we work weekends if we need to. But it’s a year-round thing.

Pat: It is, and because it 80% of the work is done off-camera. So if you see it built, we’re the ones that did the work. We do machining. We do the parts planning. So with schedules, we’re just like you. Sometimes we are short on parts. Sometimes things just take longer than they should. But you’re never really working when you enjoy what you do. So the hours aren’t the big deal. We love to do what we do, so just whatever time it takes, it takes.

9. Engine Power’s Plan for Import Engines

Q: “Do you plan on doing more with import and Euro engines?”

Pat: Excellent question, well, nothing is out of the question for us, right? Because we are engine people. If it burns gasoline, we like it, and we’re about horsepower per cubic inch. So, I mean I may or may not think we might have something. Maybe?

Frankie: Maybe. The big deal is if we can run it and we can get it on the dyno, then we can do it. Yeah, like he said we’re not biased at all. We like horsepower per cubic inch. We like cylinder pressure no matter how that comes. So yeah, we may or may not be working on a few ideas already. But keep an eye out and maybe you’ll see.

Pat: No, you need to stay tuned.

Frankie: Yeah stay tuned for sure.

10. Power Adders and Engine Wear

Q: “Do you think having more than one power adder on your engine takes more of a toll on your engine than having one power adder?” For example nitrous and supercharger combo.”

Frankie: So I think he’s asking if you have two different types of power adder, does that have more of a toll on the engine than if you just had one type of power adder?

Pat: If those power adders add up to a lot of power, all the engine knows is cylinder pressure. All the parts know is how much heat, and pressure gets put to them. So whatever is trying to be contained in that cylinder case and in that combustion chamber, in that cylinder, that’s all it knows. So if it’s one, two, five, or naturally aspirated, doesn’t matter. All the engine knows a cylinder pressure

Frankie: Yeah, so it’s kind of a “yes” and a “no” if you’re adding another one and increasing the cylinder pressure. It’s going to take more of a toll on the engine if you’re reaching the same cylinder pressure with a couple of different kinds of power adders. The engine doesn’t necessarily know the difference. It knows the cylinder pressure, the power it’s making, and the heat it’s producing, and the parts obviously have to be durable enough to actually live through that. So that’s something that we take into consideration and all engine builders do when they’re picking out the parts for their build

Pat: Yeah, the power kills the part so make sure you have the right parts for the amount of power you want to make

So there you have it! 10 questions. 10 answers. Great success!