How To Verify A New Camshaft For An Old Project

In the shops, the guys verify parts for each and every project. Whether you’re building something mild or wild, it’s an important step – you want to make sure you have the correct part and that it fits properly before you’re in the middle of the build and it’s too late.

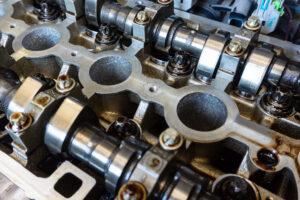

As an example, Mike and Pat are going to show you how they verify a new camshaft for an old project. The first step is to make sure the camshaft’s specs are what the cam card says they are. You can do that by measuring yourself. To start, you need to see where the intake centerline falls which is done by degreeing the cam. Take the number 0.0050 before and 0.0050 after peak lobe lift on the intake side. Then add those two numbers together and divide them by two. That will give you your intake centerline.

Now that the cam is degreed, you can compare actual lobe lift to what the cam card says. This can vary a few thousandths from the card but that’s not a big concern. You can check this by simply putting a dial indicator on the push rod and measuring the amount of travel from the lobe’s base circle to its peak lift.

The next measurement is lift at the valve. You can measure this by installing the new rocker arms for mockup. The indicator is moved to the retainer and the engine is turned over until peak lift is reached. Lobe lift multiplied by rocker ratio equals your peak valve lift. Changing rocker ratios will increase lift but be aware this can also cause interference issues depending on your components.