AMC Build-up

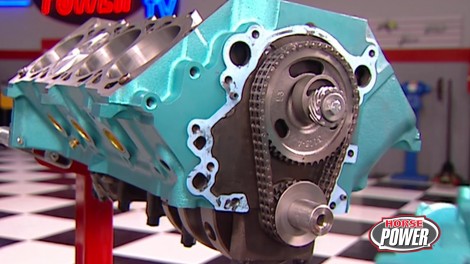

In this episode, we turn a rare Rambler into a mean street-ready machine, starting with an AMC Machine 401 block outfitted with high-performance components aimed at achieving 500 horsepower on pump gas. We also visit a father-and-son-led racing team that parlayed their love for speed into a successful high-performance parts distribution center, connecting with fellow racing enthusiasts worldwide.

Season 6

Episode 6

Hosts: Joe Elmore, Chuck Hanson

First Air Date: September 23, 2022

Duration: 21 minutes 58 seconds