Sparking Success: A Step-by-Step Guide to Installing Your Engine Distributor with Ease

When it comes to engine work, every step matters. That is why we will be going over one of the most essential steps in many engine builds – how to install a distributor. Installing a distributor is a common topic that we get constant questions about, and many are curious to know how we hit the mark, get the timing right, and have the engine spark up immediately after installation. Believe us when we say that no magic is involved, it’s simply a matter of understanding positioning and process. So we are going to go through how it’s done for every engine with a distributor, pay attention and take notes.

Step One: Find Top Dead Center

The first thing you need to do when installing your distributor is to make sure that the number one cylinder is coming up on Top Dead Center (TDC) on the compression stroke. There are a few ways to do this. The first, and generally easiest way, is by removing the number one cylinder’s spark plug. Once that is out, place your finger over the hole and cautiously turn the engine over. When the piston is coming up on the compression stroke, it will cause air to be forced out of the cylinder and push your finger off its seal, signaling you that you are on the right track.

A second, more involved method, involves pulling off a valve cover. As you rotate the engine, watch for when both valves are closed and there’s no movement from the rockers. That’s when you’re coming up on the compression stroke. After that, carefully and slowly turn the crank until the timing mark, (or Zero depending on your balancer), is about 30 degrees before Top Dead Center (TDC) on the timing pointer.

Step Two: Drop In The Distributor

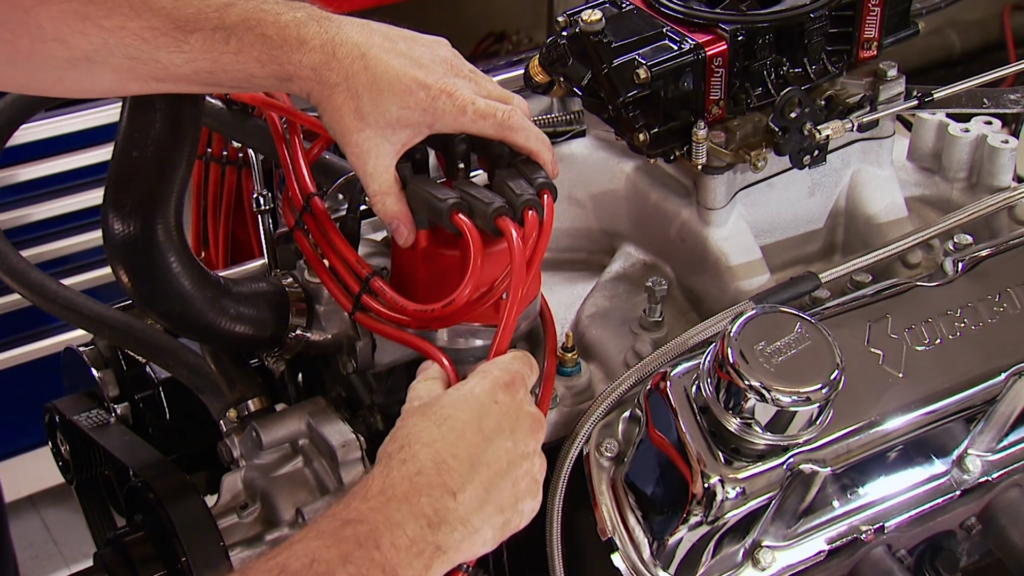

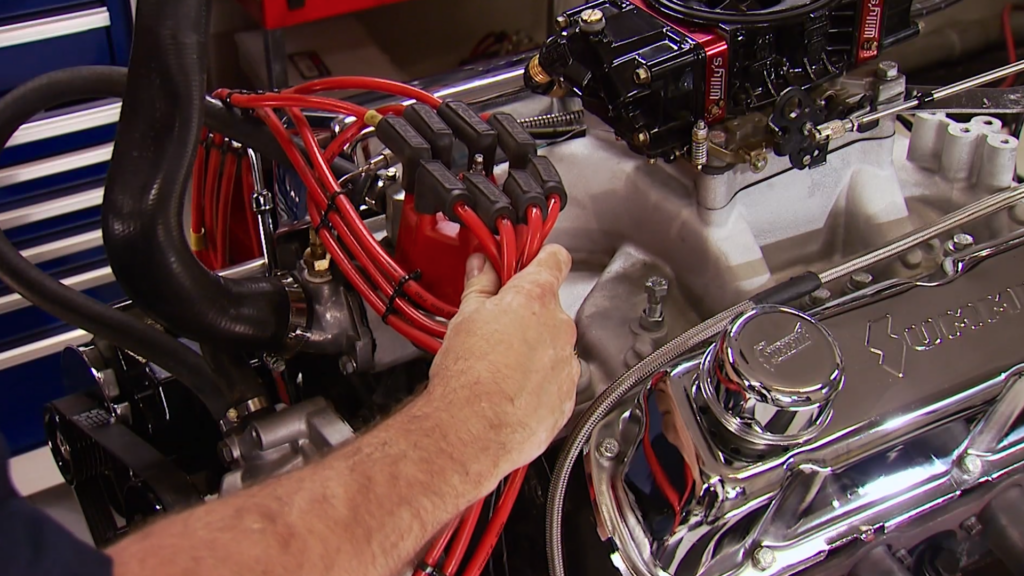

Now that you’ve reached Top Dead Center, it’s time to install the distributor. The key is to position the rotor where you want it, rather than where it falls naturally. This is important for the distributor wire routing to look neat and clean. To simplify the process and make the distributor fall right in, you have to rotate the engine a bit so that the distributor will index the oil pump drive. Lastly, simply reverse the rotation back to 30 degrees before the TDC mark.

Step Three: Ignition – The Moment of Truth

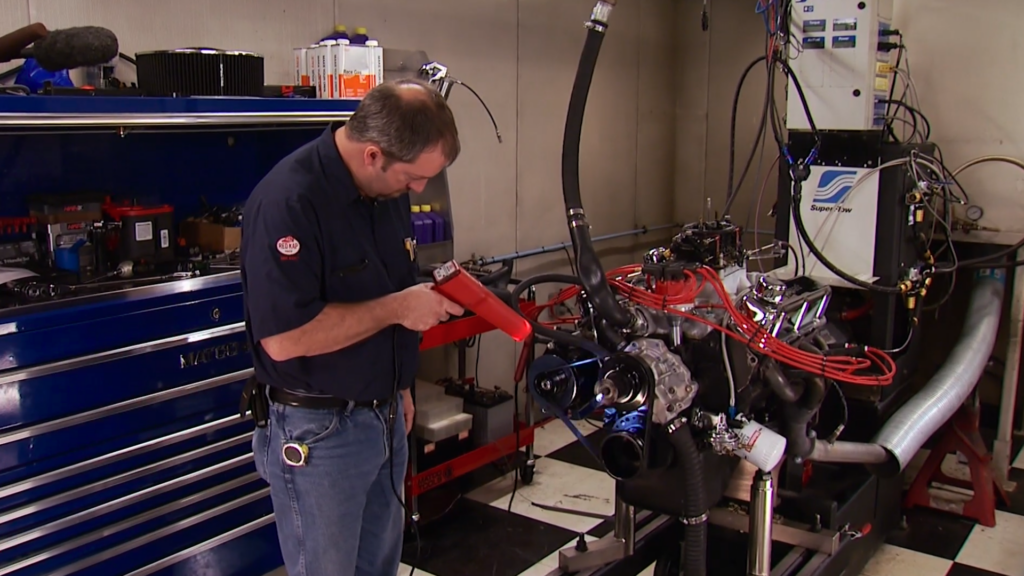

Now that we have these in place, the cap goes on, the wires are routed to the respective spark plugs and the results speak for themselves. With this simple yet effective method, never again would you relive the nightmare of seeing flames emerge from your carburetor. Not having your engine on fire will indeed make your life much simpler, and your ride smoother.

So, there you have it, how to install a distributor made easy. Be sure to be patient, pay attention to the details and you’ll find yourself mastering it in no time. Good luck and remember, it’s the little things that make an engine great.